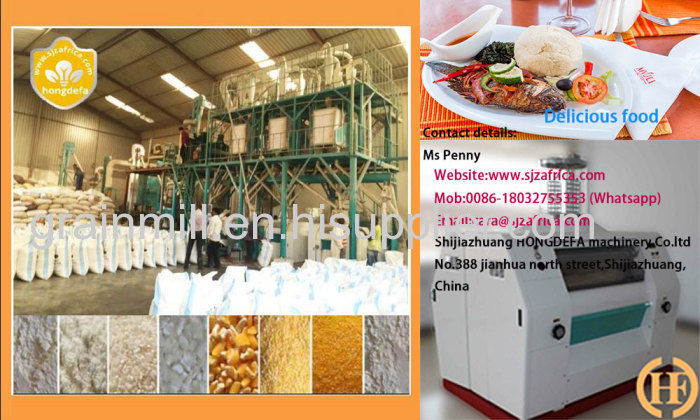

Africa maize milling mill machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU, Money Gram |

| Supply Ability: | 30T/D |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | Maize Mill, Wheat Flour Mill, Corn Flour Mill |

Product Detail

| Model No.: | HDFM 30T |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HDF |

| Capacity: | 30TPD maize milling mill machine |

| Degerminator: | Japan Technology |

| Pipes: | Stainless seteel in milling system |

| Controlling: | Touch screen |

| Final products: | Super white maize meal |

| Successful Installation: | Zambia, Kenya, Uganda, Malawi, Congo |

| Branch office: | Lusaka, Zambia |

| Production Capacity: | 30T/D |

| Packing: | Suitable for Sea Transportation |

| Delivery Date: | 30 days after payment |

Product Description

Africa maize milling mill machine

1. maize mill runin 150T/D, 50T/D, 20T/D In Kenya, Zambia, Uganda, Tanzania

2. Super white maize meal

3. Stainless steel pipes

4. Japan Technical degernimator

Model | 100T/24H Maize/Corn Flour and Grits Milling Machine |

Production capacity (T/24h) | 100-120Tons/24h of corn/maize |

Main machines and | High efficiency vibration sifter, Destoner,Washer stoner, Damper, |

Products and extraction rate (%) | Corn flour: 40-50% |

Products quality | Sand content: ≤0.02% |

Power required (kW) | 385Kw |

Size of workshop: (L×W×H, m) | 3-storey building or single storey workshop (25×8×10) |

| Countries | Year |

10 and 20 and 30 ton/24h | Zimbabwe | 2009 |

RD Congo | 2010 | |

Kenya | 2015 | |

Zambia | 2015 | |

Zambia | 2013 | |

RD Congo | 2011 | |

Uganda | 2014 | |

Angola | 2013 | |

50tons/24h maize flour milling machies | Malawi | 2009 |

Kenya | 2014 | |

Zimbabwe | 2010 | |

Tanzania | 2014 | |

Argentina | 2010 | |

Kenya | 2013 | |

Zambia | 2015 | |

Uganda | 2014 | |

100tons/24h maize flour milling mahine | South Africa | 2011 |

Zambia | 2015 |

Q: Which kind flour mill you can processed ? And the output ?

A: we can offer corn/maize mill with the capacity 5T/24H ------500T/24H .

Q: what is the basic processing step?

A: Full automatic line : Cleaning the raw material------Milling the material into flour--------Packing the flour into bags.

Q:Which kind of maize we can use in the processing line ?

A: Yellow corn/maize, White corn/maize

Q :Which kind final products we can get from the maize / corn flour mill ?

A: maize flour, maize grits (meal),maize germ, bran and animal fodder.

Contact details: