Extruder screw and barrel for plastic machine for PE screw

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR |

| Payment Terms: | L/C, D/P, D/A, T/T, Money Gram |

| Supply Ability: | 800 SET/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Ball Screw |

Product Detail

| Model No.: | screw barrel |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | ENBECO |

| Model number: | Dia 15-300mm |

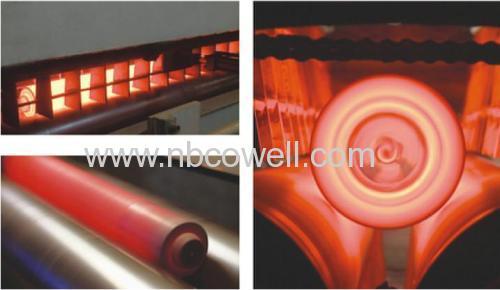

| Steel material: | 38CrMoALA, SACM645, SKD61 |

| Heat treatment: | Thermo refining, Quenching |

| Surface treatment: | Bimetllic spraying,grooves spraying etc |

| Manufacturing standard: | GB/T 15389-1994,DIN5480 etc |

| Depth of Nitriding layer: | 0.5-0.8 mm |

| Depth of Bimetallic layer: | 2 - 4 mm |

| Inner packing: | PE firm with erosion proof oil |

| Outer packing: | Plywood case |

| Rotating direction type: | Co-rotating or counter-rotating |

| Production Capacity: | 800 SET/Month |

| Packing: | Plywood case |

| Delivery Date: | 25-30 working day |

Product Description

Extruder screw and barrel for plastic machine for PE screw

Extruder screw and barrel for foaming machine

SPECIFICATION OF SCREW BARREL(for extruder, extrusion processing line)

FOR SCREW Dia. 15-300 mm Length 300-6000 mm L/D ratio: 15-50

FOR BARREL Dia. 60-600 mm Length 300-6000 mm

MECHANICAL PROPERTIES:

| Heat treatment | Nitriding 96 hours |

| Depth of Nitrated Layer | 0.5-0.8mm |

| Hardness of Nitration | HRC 56-58 |

| Depth of Bimetallic layer | 2-4 mm |

| Hardness of Bimetallic layer | HRC62-64,Above HRC64 |

| Fragility of Nitration | Less than grade 1 |

| Surface Roughness | Ra 0.4um |

Grade available:

1. Standard grade: 38CrMoAlA + nitriding 96 hours

2. Bimetallic grade: 38CrMoAlA + bimetallic alloy

3. TC-A grade: Tungsten carbide 40%

4. TC-B grade: Tungsten carbide 25%

5. TC-C grade: Tungsten carbide 15%

Packaging & Shipping

Inner packing: PE film with erosion proof oil film

Outer packing: Plywood case

Shipping ways: By sea, by air, by train and by express

Our Services

1. Measure dimension of screw and barrel

2. Complete manufacturing drawing

3. Making optimal solution based customers required

4.Calculated the cost of goods

5.Taking photos of finished products

6 Booking ship and make shipping schedule.

7.Send custom clearance documents.

8.Arrange factory visiting schedule

9.Assitant with customers to deal other matters

Company Information

As a professional manufacturer and supplier of screw barrel, we can make any specifcation of extruder screw barrel for Haitian, Demag, Engel, Krauss maffei, Battenfeld, Nigro bossi, Arburg, NPM, BOY, Husky, Fanuc, Billion, Sumitomo, JSW, Toshiba, Nissei, Mitsubishi etc.

| Year Company Established | 2006 |

| Total No. of Staff | 51 – 100 People |

| Business Type | Manufacturer |

| Main Export Markets | Western Europe, Eastern Europe, South America, |

| Southeast Asia, Mid East, Africa |