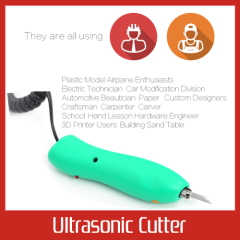

WOYO Ultrasonic Cutter Cutting Plastics Hobby Tool

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 235 |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Cutting Tool, Auto Parts |

Product Detail

| Model No.: | W2 |

|---|---|

| Means of Transport: | Air |

| Type: | Car |

| Style: | Others |

| Material: | Plastic |

| Brand Name: | WOYO SMART |

| Production Capacity: | 235 |

| Packing: | Carton |

| Delivery Date: | 3 days |

Product Description

1. The trim cut surface :Compared to traditional iron tools such as electric drills,cutting surface uniformity is significantly improved (part of the material's melting phenomenon will appear).

2.Fast speed,save labour: working in high-speed characteristics of the blade driven by the host, compared to traditional tools, the speed has improved significantly.

3. Convenient:Just press the switch on the handle,and it can be cut, beside opening more convenient on planar objects specially.

4. Energy saving: about 20 to 25 w of power consumption.

5.Environment protection:when cutting will not produce large amounts of powder and smoke (farewell electrically heated iron, utility knives, drills and other tools).

6. Flexible:very suitable for operation in small places.

7. Safety:contact point switch, make you more safe operation.

Ultrasonic Cutter ultrasonic fabric cutter

Ultrasonic Cutting applications Ultrasonic Cutting machine

sound modification