110/220+92/188 Co-extrusion flooring production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | BOYU |

| Certificate: | UL,CE,TUV,CSA,ISO |

| Automation: | Automatic |

| Function: | Flooring extrusion |

| Production Capacity: | 20sets/month |

| Packing: | wooden case packing or film |

| Delivery Date: | 30~90 days |

Product Description

PP Flooring Production Line

Advantages of PP floor

1.PP floor has low density and lighter weight than SPC floor

2.Responding to the EU's plastic ban

3.PP material is degradable

4.PP floor is halogen-free and smoke-free during the combustion process

5.The fire rating of PP flooring is v1-v0

Advantages of BOYU's PP flooring production line

1.Power-saving

2.High productivity

3.Intelligent electronic control system

4.Stable performance and low failure rate

1.Design parameters

No. | Items | Data |

01 | Total Power | 520KW |

02 | Raw Material | PP powder, calcium carbonate, stabilizer, lubricant, small materials |

03 | Main material proportion | PP: CACO3= 1:3 |

04 | Product specifications | Width:985/1220/1860mm,Thickness:3-9mm |

05 | Machine Fabrication Certificate | CE |

06 | Electric components certificate | CE |

2.Equipment List

Extruder → T-die → Four rollers Calender → Oil temperature controller →Two rollers embossing machine → Traction machine → Cutting machine → Automatic flipper & Stacker

3.Extruder model

Model No. | Screw specifications Φ(mm) | Capacity/h | Installed power | Operating power |

BOYU-A | Φ90*2 | 1 Ton | 320 KW | 220 KW |

BOYU-B | Φ135 | 1.5 Ton | 400 KW | 280 KW |

BOYU-C | Φ160 | 2.5 Ton | 500 KW | 350 KW |

4.Finished board

5.EIR Patent

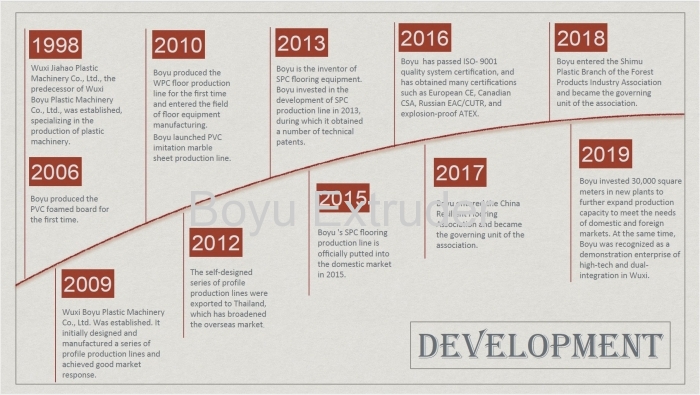

6.Boyu Development

7.Our Services:

8.Shipping