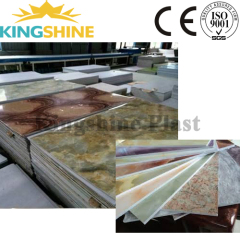

Artificial marble sheet production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 20sets/moth |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | BYSJ |

|---|---|

| Means of Transport: | Ocean |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | BOYU |

| Power: | 75KW |

| Capacity: | 350-400kg/hr |

| Certification: | SGS,BV,CE |

| Delivery Time: | 30 working days |

| Control Way: | PLC |

| Production Capacity: | 20sets/moth |

| Packing: | film packing |

| Delivery Date: | 30days |

Product Description

1.Application:

Pattern: marble, carpet, stones, natural scenery, stereo design, etc, customized pattern.

Function and features: sound insulation, soft, easy to clean, comfortable feet feeling, personalized color and design,

Unique advantage: we can make any pictures as you want without repeat

Thickness: 1.5mm, 2.2mm, 3.2mm and 8.0mm

PVC sheet extrusion line

Thickness: 1.0-5.0mm

Wear layer: 0.07-0.7mm

Product Description

Taking advantages of its practical, affordable and simple features, this wood texture vinyl flooring is widely applied to home, office, school, supermarket and hospital as the ideal decoration material. As a high quality vinyl plank, it has stood the test of time and market.

Product Advantages

1. Selecting the superior quality of raw material.

2. A wide range of applications.

3. Simple and practical design, easy to install.

4. Offering an affordable price but excellent quality.

5. Various choices of color and size.

5. High performance water proof, anti-slip, fire resistance and wear resistance.

Usual Products Sizes:

1. Usual sheet width: 700, 900, 1020, 1200, 1300, 1400, 1500, 1700, 1800, 2100, 2200mm

2. Usual sheet thickness: 0.5-2mm, 1.5-10mm, 6-20mm, 3-30mm

PVC PP PE sheet extrusion line main features:

1.Well designed well made high quality extruder with special use helical gear reducer and high efficiency converter motors, make high speed extrusion, single screw for PP PE material, conical double screw for PVC material;

2.Special screw structure, high shear stress and low temperature, ensure high quality plasticization;

3.High precise T-type die head, indepedent oil temperature control chromed 3-roller calender, uniform speed and high traction force NBR roller haul-off machine help making uniform thickness PVC PP PE sheet;

4.Whole line with high degree of automation, easy to operate;

5.High quality steel materials, strict producing process make high quality line;

6.New advanced energy saving technology, lowered energy consumption;

7.Whole line adopt newest design concept, using well known brand electrical components, enhanced line stability.

THIS EXTRUSION LINE CONSISTS OF :

1. Spring Feeding Machine

3.T-Type Die Head

4.Three-roller Calendar

5.Cooling Frame

6.Edge Cutting Machine

7.Hauling off Machine

8.Knife Cutting Machine

9.Stacker

2.Main machine for polishing line

3.service:

Pre-sale for PVC profile machine:

We provide presales service in various forms, for example, making investment budget,manufacturing planning, etc. so that customers make a reasonable plan with less cost.

• Investment budgeting: We provide services of product profit analysis, recommendation of machine and auxiliary equipment and relevant budgeting, human resources allocation and budgeting.

• Plant Planning: We provide the mounting dimension of the equipment base,design of equipment layout, workshop ventilation, water transmission etc.

• Offer information of peripherals In-sale for PVC profile machine:

• Detailed design of lay-out that is the position of the procession

• Technological information of provided products

• Schedule about design,manufacturing and installation

• Working & Producing progression

• Training course for the technician so that the installation is safe and standard

After-sale for PVC profile machine:

• For customers buying our products, we provide them free training so that they can use and maintain the machine independently.

• We will answer customer's question on technology in time. If needed, we will offer on-site guidance and assistance.

• We can provide free technical guidance if customers need new equipment, add or rebuild equipment.

• We will prioritize the product upgrade of former customers.