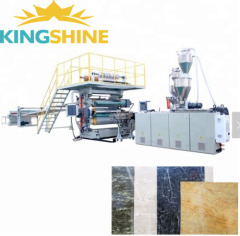

PVC Imitation marble sheet making machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 20sets/moth |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | BYSJ |

|---|---|

| Means of Transport: | Ocean |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | BOYU |

| Power: | 75KW |

| Capacity: | 350-400kg/hr |

| Delivery Time: | 30 working days |

| Control Way: | PLC |

| Certification: | SGS,BV,CE |

| Production Capacity: | 20sets/moth |

| Packing: | film packing |

| Delivery Date: | 30days |

Product Description

Plastic PVC imitation marble sheet making machine line

Brief Introduction:

Imitation marble board made of PVC material, has the water-proof,anti-corrosion and light quality effects.

The product has marble pattern, granite pattern , imitation wood grain, rationale pattern, solid color semipermeable heart and other patterns.

It has such characteristics as flame retardant, anti-corrosion, non-slip, resistant to pressure, stable quality, low prices and simple construction, compared with other flooring materials with better performance, better decorative effect, is suitable for the movable plank house, factories, shopping malls, home, office and other occasions.

Charactors:

Clear grains, no color difference, wear-resistant surface, hardness up to 3H-6H, B1 level flameproof, no radiation, the lowest outdoor aging up to 15 years, the weight is 1/6 of the natural stone,with small impact on building load, can be a large area of paving,and the price is only 1/10 of the natural stone.

Natural stone is generally wet on dry hanging,has high construction costs, but the imitation marble construction which use structural adhesive or glass adhesive, can be fast and firm.

One construction worker can install thirty to forty square meters every day. Imitation marble material can achieve seamless splicing, you can also choose a 45-degree angle cut, V-groove and so on.

PVC Imitation Marble sheet/plate Production Line:

PVC raw materials Loading and Mixing system | |

1. Spiral Loader or Vacuum auto Loader | 1 set |

2. High speed Heating Cooling Mixer unit | 1 set |

PVC marble sheet Extrusion Line | |

1. Spring Loader or Spiral Loader | 1 set |

2. SJZ80/156 Conical double screw Extruder | 1 set |

3. Mold/Die head Set | 1 set |

4. Three-roller Calander with Marble film unit | 1 set |

5. Temperature controller of three rollers | 1 set |

6. Cooling frame with side cutting | 1 set |

7. Haul off unit | 1 set |

8. Cutting unit | 1 set |

9. Stacker | 1 set |

Sheet/Plate Recycling machines | |

1. Sheet Crusher/Grinder | 1 set |

2. PVC Pulverizer/Miller | 1 set |

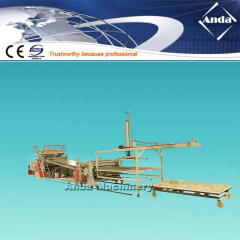

PVC Imitation Marble/ Decorative Profiles Production Line:

PVC raw materials Loading and Mixing system | |

1. Spiral Loader or Vacuum auto Loader | 1 set |

2. High speed Heating Cooling Mixer unit | 1 set |

PVC marble profiles Extrusion Line | |

1. Spring Loader or Spiral Loader | 1 set |

1 set | |

3. Mold/Die head Set | 1 set |

4. Vacuum calibration Table | 1 set |

5. Thermal Printer | Multiple sets |

6. Haul off unit | 1 set |

7. Cutting unit | 1 set |

8. Stacker | 1 set |

Profiles Recycling machines | |

1. Sheet/Plate Crusher/Grinder | 1 set |

2. PVC Pulverizer/Miller | 1 set |

Our main products:

1, WPC PVC foam board extrusion production line;

2, WPC PVCdoor board extrusion production line;

3, PVC Artifical marble extrusion production line;

4, WPC(PE/PP/PVC+wood) profile extrusion production line;

5, PVC ceiling panel profile extrusion production line;

6,Plastic auxiliary equipment.