Distributed vapour recovery system sale

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 3000set per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Type: | Diaphragm |

| Power Source: | AC Power |

| Configuration: | Others |

| Lubrication Style: | Others |

| Top brand in China: | Atex certificate |

| adapt to different environments: | easy to operate |

| environment protect: | save product |

| easy to operate: | customizable |

| long working life: | high technology |

| Production Capacity: | 3000set per month |

| Packing: | wooden case |

| Delivery Date: | 21 working days |

Product Description

Censtar is a fuel dispenser suppliers established in 1992, located in Zhengzhou City, Henan province, central China.

758 employees and possesses 80000M2 land, with a fixed asset of 800 million RMB. censtar

Annual production Capacity reaches 100,000 nozzles of Fuel Dispenser.

Main products as Fuel dispensers, Automatic Tank Gauge System, Petrol station management system and Petrol stations IC card management system etc.

It is the first and sole dispenser pumps suppliers company that reaches annual output and sales more than 100,000 nozzles of Fuel Dispenser. Its production capacity ranks No. 1 in China and third in the world.

For 17 consecutive years, Censtar keep the No. 1 position of output and sales of fuel dispenser suppliers in China.

Censtar is a dispenser pumps suppliers focus on ensuring quality of care to our clients by placing their needs at the forefront of what we do.

Our Mission is a best diesel pump manufacturers to provide complete Equipment Solutions to Retail Petroleum Industry.censtar

Service and quality is what we sell, peace of mind is what you buy.

we are seeking global co-operation agents for our products.

Technical parameters:

Operating ambient temperature:-40℃~+55℃;

Relative Humidity: 20% ~ 95%

Gas-liquid ratio range:1.0 ~ 1.2

Maximum fueling rate of nozzle:45L/min

Power supply: 220V/380V 50Hz

Vacuum-assisted way to recycle vapor

HSP01 vapor recovery pump:

Technical parameters:

Model:HSP01

Set pressure:0.1Mpa

Maximum fueling rate:60L/min

Operating temperature -40 ° C ~ +55 ° C

Maximum vacuum 0.062MPa

Noise<62dB (A)

Motor power :120W/250W

Input speed : 2900rpm

HSP03 vapor recovery gear pump:

Technical parameters:

Model:HSP03

Set pressure:0.1Mpa

Maximum fueling rate:76L/min

Operating temperature -40 ° C ~ +55 ° C

Maximum vacuum 0.038MPa

Noise<70dB (A)

Input speed : 1900rpm

Patent certificate:ZL200820221146.9

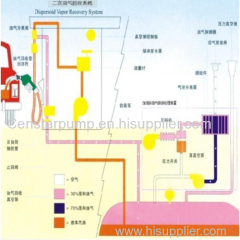

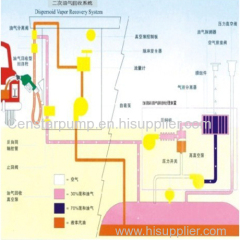

Distributed vapor recovery system details:

Stage II Vapor Recoverysystemrecoversvaportothegroundstorage tanks,vaporemissionstreatment planttransforms vaporinto liquidgasoline, it controls emissions to meet environmental standards and save a lot of energy.

Stage II Vapor Recovery system components

Vapor Recovery Nozzle

Vapor Recovery break-away valve

Coaxial hose

Vapor separator

nstallation Sample:

Production status