ZLYJ Series Dedicated Industrial Speed Reducer Gearbox for Dewatering Extruder

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Changzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Gear Speed Reducer |

Product Detail

| Model No.: | SJ12 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Processing: | Precision Casting |

| Shape: | Rack Gear |

| Standard or Nonstandard: | Nonstandard |

| Material: | Steel |

| Tooth Profile: | Others |

| Brand Name: | ZE01 |

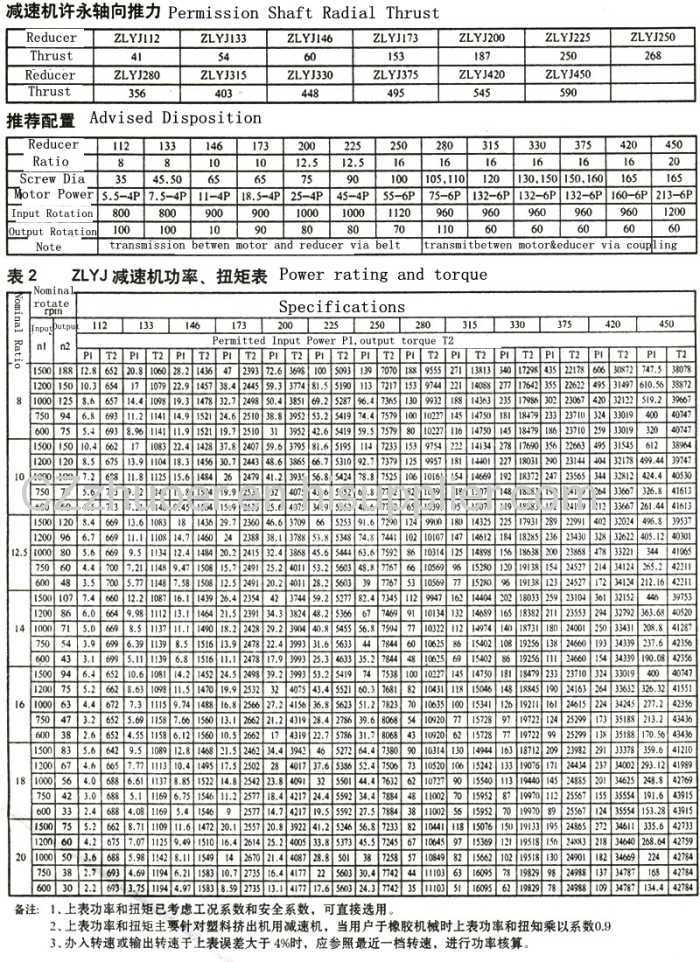

| Output torque: | 693-42784 N.m |

| Warranty: | During one year |

| Lifetime: | More than 8 years |

| Material: | Cast Iron |

| Heat Treatment: | Carburising,quenching or grinding |

| Output Type: | Shaft or hole |

| Packing: | Wooden case |

| Delivery Date: | 20 days for OEM,7 days for ready goods |

Product Description

Specification :

1, output torque:693-42784(N.m)

2, rated power:2.2-748(kw)

3, input speed:≤1500 (rpm)

4, output speed:30-188(rpm)

5, transmission:≥8-20

6, series:2

7, Model no. :ZLYJ(112-450)

Features :

1. ZLYJ series reduction gearbox is a transmission part that possesses high precision hard gear surface and thrust block designed for plastic screw extruder.

2.The design of product adapts all kinds of norm specified in ZBJ19009-88/it features that gear and axis parts are made of high strength alloy steel.

3.The gear is processes by carburization, quenching and tooth grinding process.

4.The precision of gear is grade 6 specified in GB1009588.

5.The hardness of gear surface is HRC54~62. At front end of hollow input axis there is large specification thrust bearing that will bear axial thrust force while the screw is working.

6.The complete machine features compact, high in bearing capacity, stable in transmission, low noise, high efficiency, etc.

Applicable condition:

1. The input rotation of prime mover shall be ≤1500rpm

2. The peripheral speed of gear drive shall be ≤20m/s

3. The working ambient temperature shall be within -40~45°C.Preheat the lubrication oil to above 0°C when the ambient temperature is below 0°C. Rotation is available both forwards and backwards. However, the high speed shaft of some types of reducers has a single way oil pump directing as defaulted to the output shaft which rotates clockwise.

Specifi cations | a | H | H1 | h | A | B | L1 | I1 | L2 | L3 | d1 (m6) | t1 | b1 | d2 (H8) | l4 | I2 | b2 (F9) | d3 | n 1 | Φ |

ZLYJ112 | 184 | 130 | 18 | 426 | 170 | 106 | 106 | 203 | 28 | 31 | 8 | 35 | 52 | 38.3 | 10 | M10 | 6 | 185 | ||

ZLYJ133 | 218 | 140 | 20 | 478 | 215 | 125 | 125 | 205 | 28 | 31 | 8 | 38 | 80 | 41.3 | 10 | M12 | 8 | 205 | ||

ZLYJ146 | 256 | 160 | 22 | 560 | 250 | 148 | 148 | 245 | 32 | 35 | 10 | 45 | 120 | 48.8 | 14 | M12 | 8 | 230 | ||

ZLYJ173 | 285 | 170 | 21 | 576 | 256 | 148 | 148 | 250 | 38 | 41 | 10 | 50 | 140 | 57.6 | 14*2 | M16 | 8 | 260 | ||

ZLYJ200 | 340 | 240 | 40 | 750 | 340 | 200 | 200 | 330 | 45 | 48.5 | 14 | 60 | 170 | 68.8 | 18*2 | M16 | 12 | 300 | ||

ZLYJ225 | 385 | 250 | 36 | 800 | 360 | 205 | 205 | 355 | 55 | 59 | 16 | 70 | 170 | 78.8 | 18*2 | M20 | 12 | 370 | ||

ZLYJ250 | 430 | 280 | 45 | 930 | 380 | 220 | 220 | 380 | 60 | 64 | 18 | 80 | 180 | 90.8 | 22*2 | M20 | 12 | 370 | ||

ZLYJ280 | 480 | 300 | 50 | 970 | 400 | 240 | 240 | 105 | 65 | 69 | 18 | 90 | 180 | 100.8 | 25*2 | M34 | 12 | 400 | ||

ZLYJ315 | 539 | 350 | 55 | 1160 | 450 | 250 | 250 | 440 | 75 | 79.5 | 20 | 100 | 200 | 112.8 | 28*2 | M34 | 12 | 405 | ||

ZLYJ330 | 575 | 350 | 60 | 1160 | 450 | 260 | 260 | 445 | 85 | 90 | 22 | 110 | 220 | 122.8 | 28*2 | M24 | 12 | 450 | ||

ZLYJ375 | 625 | 400 | 60 | 1280 | 466 | 265 | 265 | 445 | 85 | 90 | 22 | 110 | 255 | 122.8 | 28*2 | M24 | 12 | 450 | ||

ZLYJ420 | 695 | 460 | 80 | 1420 | 550 | 310 | 310 | 535 | 95 | 100 | 25 | 120 | 220 | 134.8 | 32*2 | M30 | 12 | 580 | ||

ZLYJ450 | 765 | 500 | 60 | 1550 | 600 | 350 | 350 | 600 | 220 | 100 | 106 | 28 | 170 | 250 | 188.8 | 40*2 | M30 | 12 | 610 | |

ZLYJ630 | 1070 | 630 | 30 | 2000 | 770 | 430 | 430 | 760 | 280 | 120 | 127 | 32 | 180 | 340 | 200.8 | 45*2 | M36 | 12 | 720 | |

ZSYJ450 | 765 | 500 | 276 | 60 | 1550 | 600 | 350 | 350 | 600 | 220 | 75 | 79.5 | 20 | 170 | 250 | 188.8 | 40*2 | M36 | 12 | 610 |

ZSYJ560 | 960 | 580 | 324 | 80 | 1850 | 610 | 355 | 355 | 670 | 260 | 95 | 100 | 25 | 160 | 300 | 178.8 | 40*2 | M36 | 12 | 720 |

ZSTH630 | 1070 | 630 | 350 | 80 | 2000 | 770 | 430 | 430 | 760 | 285 | 110 | 116 | 28 | 180 | 340 | 200.8 | 45*2 | M36 | 12 | 720 |

Specifi cations | Φ2 (H7) | I3 | Φ3 | d4 | n2 | m1 | m2 | m3 | m4 | m5 | m6 | m7 | C | D | E | d5 | d6 | l5 | M |

ZLYJ112 | 160 | 8 | 210 | 14 | 4 | 96 | 326 | 50 | 136 | 170 | M16 | 18 | 125 | ||||||

ZLYJ133 | 180 | 8 | 230 | 16 | 6 | 104 | 185 | 185 | 61 | 180 | 184 | M18 | 20 | 137 | |||||

ZLYJ146 | 200 | 8 | 260 | 16 | 6 | 118 | 190 | 235 | 72 | 210 | 210 | 85 | 38 | ZG 1/2^n | M18 | 20 | 167 | ||

ZLYJ173 | 230 | 8 | 300 | 17.5 | 6 | 113.5 | 220 | 220 | 68 | 225 | 214 | M20 | 25 | 167 | |||||

ZLYJ200 | 270 | 8 | 350 | 18 | 6 | 150 | 275 | 275 | 100 | 290 | 310 | 120 | 40 | M85*4 | 40 | 50 | 250 | ||

ZLYJ225 | 330 | 8 | 420 | 26 | 6 | 165 | 310 | 310 | 90 | 315 | 330 | 140 | 50 | 55 | 265 | ||||

ZLYJ250 | 330 | 8 | 420 | 26 | 6 | 205 | 360 | 360 | 105 | 330 | 340 | 160 | 50 | 285 | |||||

ZLYJ280 | 360 | 8 | 450 | 30 | 6 | 200 | 385 | 385 | 100 | 355 | 380 | 160 | 50 | 300 | |||||

ZLYJ315 | 365 | 8 | 450 | 30 | 6 | 261 | 450 | 450 | 150 | 390 | 460 | 160 | 55 | M90*4 | 335 | ||||

ZLYJ330 | 400 | 10 | 500 | 60 | 8 | 225 | 450 | 450 | 150 | 390 | 425 | 160 | 55 | M85*4 | 60 | 60 | 350 | ||

ZLYJ375 | 400 | 10 | 500 | 32 | 8 | 25 | 475 | 500 | 165 | 265 | 400 | 500 | 160 | 55 | ZG 3/4^n | M90*4 | 60 | 60 | 345 |

ZLYJ420 | 500 | 10 | 660 | 32 | 8 | 305 | 580 | 540 | 150 | 328 | 480 | 200 | 60 | 370 | |||||

ZLYJ450 | 500 | 10 | 700 | 32 | 8 | 300 | 600 | 600 | 190 | 300 | 520 | 200 | 60 | 515 | |||||

ZLYJ630 | 650 | 25 | 805 | 48 | 8 | 400 | 850 | 800 | 200 | 450 | 670 | 300 | 80 | 495 | |||||

ZSYJ450 | 500 | 10 | 700 | 32 | 8 | 300 | 600 | 600 | 190 | 300 | 520 | 200 | 60 | 480 | |||||

ZSYJ560 | 620 | 25 | 805 | 48 | 8 | 390 | 730 | 780 | 170 | 510 | 270 | 80 | 435 | ||||||

ZSTH630 | 650 | 25 | 805 | 48 | 8 | 400 | 850 | 800 | 200 | 450 | 670 | 300 | 80 | 520 |

Model | Oil Pump | Cooling Coil (Inside) | Cooler | Note |

ZLYJ112 | None | None | None | Natural Cooling |

ZLYJ133 | None | None | None | Natural Cooling |

ZLYJ146 | None | None | None | Natural Cooling |

ZLYJ173 | None | Available | None | State when ordering |

ZLYJ200 | Available | Available | None | State when ordering |

ZLYJ225 | Available | Available | None | State when ordering |

ZLYJ250 | Available | Available | None | State when ordering |

ZLYJ280 | Available | Available | None | |

ZLYJ315 | Available | Available | None | |

ZLYJ330 | Available | Available | Available | |

ZLYJ375 | Available | Available | Available | |

ZLYJ420 | Available | Available | Available | |

ZLYJ450 | Available | Available | Available |

Services:

1. Before product acceptance, we will answer all of your questions in a timely manner, provide technical support.

2. Our technical services group will provide technical support for products repair and maintenance.

3. Our commitment is to create even more value for you, keep a close contaction relationship with our customers.

4. All products with high quality, have more than 1 guarantee

5 All price will be competitive price

6. We will attend the exhibition in different country and visit our old customer to feedback information

Packaging & Delivery

Packaging Details: | Small size: standard export packing (carton and pallet); Big size: fumigated wood carton or non-wood packing material carton |

Delivery Detail: | within 25 workdays after receiving the payment |