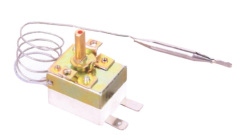

remote controller with the capillary

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, alipay, T/T, WU |

| Supply Ability: | 5000000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Thermostatic Radiator Valve, Thermal Actuator, Thermostatic Valve, Trv, Mixing Valve |

Product Detail

| Model No.: | BYL-6731 |

|---|---|

| Means of Transport: | Ocean, Air |

| Style: | Others |

| Function: | Others |

| Brand Name: | baiyilun |

| Size: | DN15 |

| Color: | White |

| Sensor: | Liquid |

| Material: | brass+Plastic |

| Temperture control range: | 6-28degree/30-70degree |

| Connecting size: | M30*1.5mm |

| Standard: | EN215 |

| Certificated: | CE,ISO9001/14000/RoHS |

| Production Capacity: | 5000000 |

| Packing: | 100pcs/carton |

| Delivery Date: | 20-25days (up to the order) |

Product Description

Long range controller inspection

Long range controller doesn't need exterior power while automatically sensing to adjust and maintain the temperature, normally used for underfloor heating systems.It is easy to fix and dismantle.

1.Long rang controller is used screw to joint on the control valve body,by adjust the controller to set the temperature range.This can keep the temperature to a certain point,in case to set at a wrong point,keeping flow rate to steady range.

2.Temperature setting

For example.you can use it to control the return water of the floor heating system,temperature of the hot water tank and so on to reach your designed temperature.Two temperature range can be chooses:From room 6-28degree;for underfloor heating system:30-70degree.

Temperature range is following.

For room:

Room temperature ℃: 6 12 16 20 24 28

Scale range: * 1 2 3 4 5

For underfloor heating system:

Room temperature ℃: 30 38 46 54 62 70

Scale range: * 1 2 3 4 5

3.Main specification

Max pressure:1.0Mpa

Max differential pressure:0.1Mpa

Size:1/2''3/4''1''

Connection size:M30*1.5

Tube length:2m

Control range:6-28degree,30-70degree

Working medium:Water

Max pressure:10bar

Stroke:3mm

4.Installation note

A. When fixing the controller to the valve body,use proper tools to screw it tight,do not use strong strength in case of broking the nut.

B.The controller should be fixed with manifold and keep them ventilating,avoid strong lights or near the hot stuffer.And not to be barred.

C.Use soft clearance liquid to clean its surface,do not use alcohol or bleach liquid or any other organic solvents.