HDPE Fabricated Elbow 45deg 3 Segments PE Pipe Fittings

| Min. Order: | 2 Piece/Pieces |

|---|---|

| Payment Terms: | D/A, T/T |

| Supply Ability: | 100 piece per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Shaoxing, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PP/Steel Backing Ring For Stub End, HDPE Fabricated Cross Tee, HDPE Fabricated Wye Tee 45deg, HDPE Segmented Elbow 45deg, HDPE Butt Fusion Y Tee Branch Tee Lateral Tee |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Head Code: | Others |

| Shape: | Equal |

| Technics: | Others |

| Type: | Elbow |

| Material: | Plastic |

| Connection: | Welding |

| Process: | Fabricated |

| Size: | dn50 to dn1600 |

| Standard: | ISO4427 BS EN12201 |

| R: | 5D available |

| Production Capacity: | 100 piece per month |

| Packing: | bulk |

| Delivery Date: | Within 10 days regularly |

Product Description

Description

Segmented Fittings are state of the art for large diameter polyethylene pressure pipe systems. The maximum injection molded fittings in BES Fusion are until OD 630mm available, with molded stub ends and End cap up to OD 1600mm available. In larger diameters segmented fittings are the first choice. To guarantee the required homogeneity, stability and strength it is most important to use a high quality pipe and a proper welding-technology.

It is important to be aware that reductions occur to the pressure rating of PE100 fittings fabricated from PE100 pipe. A derating of the maximum allowable operating pressure applies once a workshop fabricated fitting is joined to the pipeline, and different PE fittings geometries require differing derating factors.

For tees fabricated out of pipe segments, the following derating rules for the calculation of the PN shall apply:

PN = fT×PNpipe

where fT is the derating factor for these tees, having a value of 0,5;

PNpipe is the nominal pressure of the pipe.

For bends fabricated out of pipe segments, the following derating rules for the calculation of the PN shall apply:

PN = fB×PNpipe

where Fb is the derating factor related to the bend segment design as below;

Cut Angle β | Derating factor |

≤7.5° | 1.0 |

7.5°<β≤15° | 0.8 |

PNpipe is the nominal pressure of the pipe.

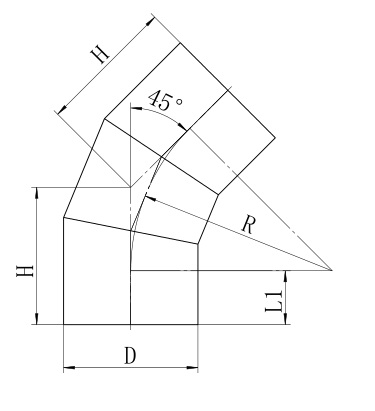

Dimensions

| D (mm) | H (mm) | L (mm) | R (mm) |

| 355 | 520 | 300 | 533 |

| 400 | 548 | 300 | 600 |

| 450 | 580 | 300 | 675 |

| 500 | 665 | 350 | 750 |

| 560 | 698 | 350 | 840 |

| 630 | 741 | 350 | 945 |

| 710 | 791 | 350 | 1065 |

| 800 | 847 | 350 | 1200 |

| 900 | 960 | 400 | 1350 |

| 1000 | 1022 | 400 | 1500 |

Note: 1, All dimensions are subjected to be changed without notice. For enginnering use,please contact with us for details.

2, Other sizes are available on request.

3,Conventional butt-welding according to DVS 2207 part 1

4,Pressure reduction factor:0.8

Approval

About Us

For more than 10 years BESFUSION has been supplying high quality polyethylene piping products to pipe manufacturers, distributors and contractors for water, gas, oil patch, sewer and industrial markets.

At BESFUSION, we strive to earn your business and consistently demonstrate our customer-driven philosophy of success. We realize that your success is our success. That's why we take such pains to make sure things are done right the first time, consistently and predictably.

To BESFUSION, quality starts with a relentless analysis of customer need and a near obsession with precision—precision to your standards as well as our own. Our commitment on uncompromising quality is documented. BESFUSION earned ISO 9001 certification and all BES HDPE pipe fittings are approved to be in compliance with ISO4427 and BS EN12201 standards.

Partnering with BESFUSION means you can trust us. Trust us to not just manufacture and supply reliable products for piping systems you service, but also trust us in finding the right way to meet the unique needs of your company. If there's a better way to do something we'll either find it or invent it to save your time and money.

That's not all. We also help you explore new ways of doing things, you know where to turn when it's time to get something innovative done. At BESFUSION, customer service starts with our listening. So, if you have an interesting product idea, we would like to discuss it with you.

Factory Certification

Main Equipment In BESFUSION

Main Pipe Production Equipments Lists

| No | Equipment | Size | QTY | Manufacturer | Capacity |

| 1 | Pipe Extrusion Line | DN20/63 | 2 | Battenfeld Germany | 300kg/h |

| 2 | DN20/125 | 2 | 300kg/h | ||

| 3 | DN50/250 | 4 | 600kg/h | ||

| 4 | DN180/450 | 2 | 600kg/h | ||

| 5 | DN315/630 | 3 | 1000kg/h | ||

| 6 | DN500/800 | 3 | 1000kg/h | ||

| 7 | DN710/1600 | 1 | 1350kg/h |

Main Pipe Fittings Production Equipments Lists

| No. | Equipments | Model | Qty | Manufacturer |

| 1 | Injection Molding Machine | FJ1000 | 1 | China |

| 2 | FJ680 | 1 | ||

| 3 | FJ650 | 1 | ||

| 4 | FJ580 | 1 | ||

| 5 | FJ480 | 1 | ||

| 6 | FT430 | 1 | ||

| 7 | FT330 | 1 | ||

| 8 | FT300 | 1 | ||

| 9 | FT200 | 1 | ||

| 10 | 1600T Hydraulic Press Machine | XLB-2100-1800 | 1 | |

| 11 | Thermal Fusion Welding Machine | SHG315/160 | 3 | |

| 12 | Thermal Fusion Welding Machine | SHG630/355 | 1 | |

| 13 | Thermal Fusion Welding Machine | SHG710/1600 | 1 | KWH Finland |

| 14 | Multi Angle Bandsaw Machine | SJC-630/90 | 1 | China |

| 15 | YGJ-1600/710 | 1 | ||

| 16 | Saddle Welding Machine | M315/160 | 1 | |

| 17 | M800/355 | 1 | ||

| 18 | M1600/900 | 1 |

Other Subsidiary Production Equipment

| No. | Equipment | Model | QTY | Manufacturer |

| 1 | Raw Material Dehumidifiying Dryer | D-800 | 4 | Kawata Japan |

| 2 | Worm Type Compressor | 24KT.LS-10 | 4 | China |

| 3 | Vaccum Pump | 2BV5131-0KL00-7P | 3 | Simens |

| 4 | Water chilling unit | KLS-470WS | 4 | China |

| 5 | Cooling Tower | JL-150 | 4 | China |

| 6 | High-speed Mixer | SHR-200A | 1 | China |

| 7 | SHR-500A | 3 | China |

Main Testing Equipment List

| Equipment | Model | QTY | Unit | Manufacturer |

| Pull Strenght Testing Machine | XLD—20 | 1 | Set | China |

| VI CAT Plusis Tester | XRW—300H5 | 1 | Set | |

| MFR Tester | XNR—400R | 1 | Set | |

| W.P/B.P Pressure Tester | XGB—10 | 2 | Set | |

| Drop Hammer Impact Tester | XJL—300C | 1 | Set | |

| Photoelectric Analytical Aalance | TG328B | 1 | Set | |

| Electric Analytical Aalance | HR-120 | 1 | Set | AD JAPAN |

| Table Balance | BP—Ⅱ | 1 | Set | China |

| Moisture Meter | KF—1B | 1 | Set | |

| Differential Scanning Calorimeter | DSC200PC | 1 | Set | NETZSCH Germany |

| Environmental Stress Cracking Resistance tester | NYK—06 | 1 | Set | China |

| Electric heating constant temperature drying oven | SZ101—1 | 1 | Set | |

| Electric heating constant temperature drying oven | SZ101—1 | 1 | Set | |

| Hydrostatic strength Tester | XGB—10 | 2 | Set | |

| Constant temperature test chamber | SGHS—1 | 1 | Set | |

| Constant temperature test chamber | SGHS—2 | 1 | Set | |

| Dumbbell system prototype | XYZ—12 | 1 | Set | |

| Digital microhm meter | PCGA | 1 | Set |

Main Projects List

| NO | Description of Project | Brief Description Of Goods |

| 1 | Countryside water supply project in Haian City | HDPE Pipes and Fittings,from dn20 to dn500 SDR17-SDR11,67400m in total. |

| 2 | Urban Water Supply Project In Shaodong City | HDPE Pipes and Fittings,dn900 SDR21, 9300m in total. |

| 3 | Countryside Water Supply Project In Dexing City | HDPE Pipes and Fittings,dn20-dn315, SDR21-SDR11, 798600m in total. |

| 6 | Town East Of Colombo District Water Supply Project | HDPE Pipes and Fittings,dn20 to dn315 ,SDR11,SDR17, 790000m in total. |

| 7 | Municipal of Bauan and San Pascual,Batangas in Philippines | HDPE Pipes and Fittins,dn20 to dn315,SDR11,SDR17 |

| 8 | The largest Ocean Park project nationwide:pipeline engineering from Zhuhai Changlong Ocean Kingdom to Ocean Wonders Sustenance System | HDPE Pipes and Fittings,dn450 to dn1200, 8500m in total |

| 9 | Landscape water diversion project of 2008 Beijing Olympics (South gate of Tiantan-Diaoyutai state guesthouse) | HDPE Pipes and Fittins,dn900 to dn1000, 11200m in total |

| 10 | Key project of comprehensively using national new energy :Water diversion project of Dalian Bay. | HDPE Pipes and Fittins dn1200 to dn1600mm,7500m in total |

| 11 | The largest deep-sea discharge project nationwide:the sea outfall project of chemical industrial zone in Binhai, Jiangsu Province | HDPE Pipes and Fittins dn1000,9500m in total, with 7000m laying undersea. |

| 12 | pipe network engineering for water supply in Deqing, Zhejiang Province | HDPE Pipes and Fittins dn800 to dn1200, 17500m in total |

| 13 | The earliest large-diameter water delivery project nationwide:Chencai reservoir Water Diversion Project from water group in Zhuji, Zhejiang Province | HDPE Pipes and Fittins dn1600, 4500m in total |

| 14 | Water Pipeline Project for Shenzhen F1 Rowing Competition | HDPE Pipes and Fittins,dn1200 to dn1400,3700m in total. |

| 16 | Xiangjiang sinking-in- river PE pipe project in Changsha City, Hunan Province | HDPE Pipes and Fittins,dn1400mm,2500m in total |

| 17 | Sink The Pipeline Construction Project of Shenzhen Bay Gym of Universiade | HDPE Pipes and Fittins, dn600 to dn1200,3500m in total |

| 18 | Phase 1 Project of Qiaotou Water Works of Western Water Supply Project in Yongjia City | HDPE Pipes and Fittins, dn90 to dn900,13000m in total |

| 19 | Jiangsu Provincial Key Project-Water Supply project of Huimin District of Jiangdu City | HDPE Pipes and Fittins,dn355 to dn1200,60000m in total |

| 20 | Sewage tail Water pressure Pipe Network Project in Wangjiang City | HDPE Pipes and Fittins,dn110 to dn710 , 16500m in total |

| 21 | Nanhai Island Water Supply project in Shantou City | HDPE Pipes and Fittins, dn900 , 3000m in total |

Factory Corner

Our Products

HDPE Pipes:dn20 to dn 1600

Socket Fusion Fittings:dn20 to dn110

Molded Butt Fusion Fittings:dn50 to dn 315,SDR11; dn355 to dn630,SDR17

Electrofusion Fittings:dn20 to dn 630

Steel Flanges,PP/ST Flanges

Fabricated Fittings: dn110 to dn 1600