PP/Steel Backing Ring(Falnge Ring) With Steel Insert For Stub End

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000ton Per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Shaoxing, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PP/Steel Backing Ring For Stub End, HDPE Fabricated Cross Tee, HDPE Fabricated Wye Tee 45deg, HDPE Segmented Elbow 45deg, HDPE Butt Fusion Y Tee Branch Tee Lateral Tee |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Head Code: | Others |

| Shape: | Others |

| Technics: | Forged |

| Type: | Flange |

| Material: | Others |

| Connection: | Flange |

| Standard: | ISO/DIN |

| Material: | PP and Steel |

| Customized Dimensions: | Available |

| PN: | PN10/PN16 |

| Production Capacity: | 1000ton Per Month |

| Packing: | Plywooden case |

| Delivery Date: | Within 10 days regularly |

Product Description

The BESFUSION PP/Steel Flange Backing Rings are designed to provide a low cost, chemically-resistant alternative to conventional galvanized and coated steel backing rings. The steel core provides strength and rigidity while the polypropylene over-molding allows for extreme chemical resistance.

Description

●Constructed with a high strength steel core and polypropylene corrosion resistant over-mold

●Dimensions complied with GB /9119:2010;ISO 7005-1:1992;DIN2501;DIN2576;EN 1092

●Applications: All types of chemical fields and industries

Plants and apparatus engineering

General mechanical engineering

●Material: PP with 30% glass fiber reinforced, Steel insert

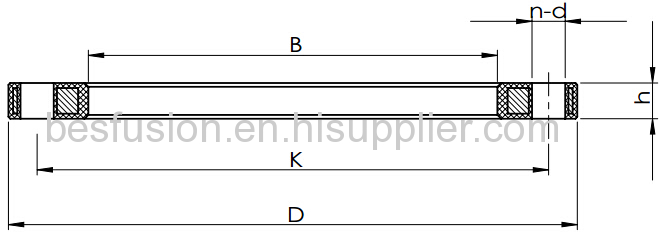

Dimensions

| DN | PE dn | D | K | B | n | d | h | PN |

| 40 | 50 | 150 | 110 | 62 | 4 | 18 | 18 | 16 |

| 50 | 63 | 165 | 125 | 78 | 4 | 18 | 18 | 16 |

| 65 | 75 | 185 | 145 | 92 | 4 | 18 | 18 | 16 |

| 65 | 75 | 185 | 145 | 92 | 8 | 18 | 18 | 16 |

| 80 | 90 | 200 | 160 | 108 | 8 | 18 | 20 | 16 |

| 100 | 110 | 220 | 180 | 128 | 8 | 18 | 20 | 16 |

| 100 | 125 | 220 | 180 | 135 | 8 | 18 | 20 | 16 |

| 125 | 125 | 250 | 210 | 135 | 8 | 18 | 22 | 16 |

| 125 | 140 | 250 | 210 | 158 | 8 | 18 | 22 | 16 |

| 150 | 160 | 285 | 240 | 178 | 8 | 22 | 22 | 16 |

| 150 | 180 | 285 | 240 | 188 | 8 | 22 | 22 | 16 |

| 200 | 200 | 340 | 295 | 235 | 12 | 22 | 24 | 16 |

| 200 | 225 | 340 | 295 | 238 | 12 | 22 | 24 | 16 |

| 250 | 250 | 405 | 355 | 288 | 12 | 26 | 26 | 16 |

| 250 | 280 | 405 | 355 | 294 | 12 | 26 | 26 | 16 |

| 300 | 315 | 460 | 410 | 338 | 12 | 26 | 28 | 16 |

| 350 | 355 | 520 | 470 | 376 | 16 | 26 | 30 | 16 |

| 400 | 400 | 580 | 525 | 430 | 16 | 30 | 32 | 16 |

| DN | PE dn | D | K | B | n | d | h | PN |

| 40 | 50 | 150 | 110 | 62 | 4 | 18 | 18 | 10 |

| 50 | 63 | 165 | 125 | 78 | 4 | 18 | 18 | 10 |

| 65 | 75 | 185 | 145 | 92 | 4 | 18 | 18 | 10 |

| 65 | 75 | 185 | 145 | 92 | 8 | 18 | 18 | 10 |

| 80 | 90 | 200 | 160 | 108 | 8 | 18 | 20 | 10 |

| 100 | 110 | 220 | 180 | 128 | 8 | 18 | 20 | 10 |

| 100 | 125 | 220 | 180 | 135 | 8 | 18 | 20 | 10 |

| 125 | 125 | 250 | 210 | 135 | 8 | 18 | 22 | 10 |

| 125 | 140 | 250 | 210 | 158 | 8 | 18 | 22 | 10 |

| 150 | 160 | 285 | 240 | 178 | 8 | 22 | 22 | 10 |

| 150 | 180 | 285 | 240 | 188 | 8 | 22 | 22 | 10 |

| 200 | 200 | 340 | 295 | 235 | 8 | 22 | 24 | 10 |

| 200 | 225 | 340 | 295 | 238 | 8 | 22 | 24 | 10 |

| 250 | 250 | 395 | 350 | 288 | 12 | 22 | 26 | 10 |

| 250 | 280 | 395 | 350 | 294 | 12 | 22 | 26 | 10 |

| 300 | 315 | 445 | 400 | 338 | 12 | 22 | 26 | 10 |

| 350 | 355 | 510 | 460 | 376 | 16 | 22 | 28 | 10 |

| 400 | 400 | 570 | 515 | 430 | 16 | 26 | 30 | 10 |

| 450 | 450 | 620 | 565 | 517 | 20 | 26 | 32 | 10 |

| 500 | 450 | 678 | 620 | 517 | 20 | 26 | 32 | 10 |

| 500 | 500 | 678 | 620 | 533 | 20 | 26 | 32 | 10 |

Note: 1, All dimensions are subjected to be changed without notice. For enginnering use,please contact with us for details.

2, Other sizes are available on request.

PP Material Characteristic as below

Characteristic | Item | Properties | Test method |

Phisical characteristic | Density | 1.14g/cm³ | ASTM D792 |

Mechanic Characteristic | Tensile Strength at break | 30 Mpa | ASTM D638 |

Elongation at break | 55% | ASTM D638 | |

Flexural Yield Strength | 45 Mpa | ASTM D790 | |

Cantilever beam notched impact strength | 5 KJ/㎡ | ASTM D256 | |

Heating Characteristic | Deflection Temprature | 130 ℃ | ASTM D648 |

Electric Characteristic | Insulation Resistance | 1016 Ω | ASTM D257 |

Dielectric Breakdown Voltage | 17 kv/mm | ASTM D149 |

About Us

For more than 10 years BESFUSION has been supplying high quality polyethylene piping products to pipe manufacturers, distributors and contractors for water, gas, oil patch, sewer and industrial markets.

At BESFUSION, we strive to earn your business and consistently demonstrate our customer-driven philosophy of success. We realize that your success is our success. That's why we take such pains to make sure things are done right the first time, consistently and predictably.

To BESFUSION, quality starts with a relentless analysis of customer need and a near obsession with precision—precision to your standards as well as our own. Our commitment on uncompromising quality is documented. BESFUSION earned ISO 9001 certification and all BES HDPE pipe fittings are approved to be in compliance with ISO4427 and BS EN12201 standards.

Partnering with BESFUSION means you can trust us. Trust us to not just manufacture and supply reliable products for piping systems you service, but also trust us in finding the right way to meet the unique needs of your company. If there's a better way to do something we'll either find it or invent it to save your time and money.

That's not all. We also help you explore new ways of doing things, you know where to turn when it's time to get something innovative done. At BESFUSION, customer service starts with our listening. So, if you have an interesting product idea, we would like to discuss it with you.

Factory Certification

Factory Corner

Our Products

HDPE Pipes:dn20 to dn1600

Socket Fusion Fittings:dn20 to dn110

Molded Butt Fusion Fittings:dn50 to dn 315,SDR11; dn355 to dn630,SDR17

Electrofusion Fittings:dn20 to dn 630

Steel Flanges,PP/ST Flanges

Fabricated Fittings: dn110 to dn 1600