PCBN Cutting Tool Blanks

| Min. Order: | 5 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 10000pcs/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Diamond Tools |

Product Detail

| Model No.: | PCBN1200-1900 |

|---|---|

| Means of Transport: | Air |

| Type: | Others |

| Style: | Others |

| Brand Name: | RJ |

| shape: | as requirements |

| diameter: | 12.7-19mm |

| thickness: | 1.6/2.0/3.2mm |

| features: | long working life |

| usage: | PCBN cutting tools |

| Production Capacity: | 10000pcs/month |

| Packing: | Plastic box |

| Delivery Date: | 7-15 workdays |

Product Description

The standard shape of RJ PCBN Cutting Tool Blanks is round. Other shapes, such as rectangle, triangle, square, semi-circle and so on, can also be customized per customers' requirements.

RJ PCBN Cutting Tool Blanks consist of fine CBN grains sintered under ultra-high pressure and ultra-high temperature. Combining the strengths of hardness, thermal stability, thermal conductivity, and strong impact resistance ability characteristic of CBN, they are ideal for cutting tools for the machining of ferrous metal and alloy, all with high productive efficiency, high machining precision, and good surface quality.

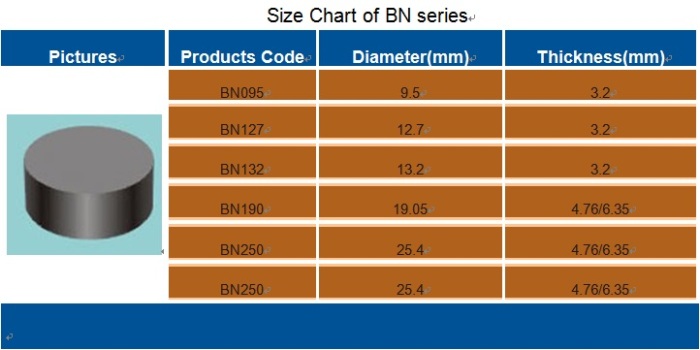

RJ CBN Cutting Tools Blanks are composed by BN and PCBN two series:

BN characteristics:

1. Solid CBN

2. Good wear resistance

3. Two sides can be used as edges

4. High thermal resistance

5. Excellent fracture resistance

BN application:

1. High Speed Turning and milling of gray cast iron

2. Turning of chilled iron, nickel-based iron and ductile iron

PCBN characteristics:

1. Good weld based in the composite CBN layer and tungsten carbide base.

2. High abrasion resistance.

3. Good transversal rupture strength resistance.

4. Good chemic stability.

5. Uniform dimension precision.

6. Good consistency of processing.

PCBN application:

1. Turning of cast iron.

2. Powdered metals.

3. Exotic materials and heat resistant alloys.

4. High speed milling of gray cast iron.

Characteristics of RJ Solid PCBN:

Product Code | Main Bond | Structural Characteristics | Application |

SBN90 | Titanium nitride | Large particles, higher wear resistance, good high-speed continuous cutting performance. | Used for cutting the iron group materials, and the cutting rate is from medium to high |

SBN80 | Cobalt, wolfram | It's the versatile material, suitable for processing various types of materials | Gray cast iron, chilled cast iron, cast iron nickel |

SBN70 | Nitrogen and carbon Titanium, Aluminium Oxide | Has excellent impact resistance and chemical stability. | Suitable for processing hardened steel with high hardness, both continuous and intermittent process |

SBN60 | Titanium carbon | High wear resistance and high impact resistance. | High-speed continuous process hardened steel |