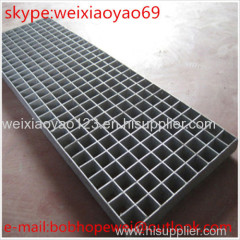

hot-dip galvanized steel grating and steel fence

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 92 Ton/Tons per Day |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Wire Mesh , Metal Wire Mesh , Window Screen , Filter Wire Mesh |

Product Detail

| Model No.: | HY |

|---|---|

| Means of Transport: | Ocean |

| Application: | Others |

| Type: | Welded |

| Material: | Others |

| Brand Name: | HY |

| Mesh Size: | 1m*2m |

| material: | hot-dipped galvanized |

| size: | 32*5mm |

| Production Capacity: | 92 Ton/Tons per Day |

| Packing: | Bundles in container |

| Delivery Date: | 10-30 days |

Product Description

Advantages

1>High strength and light structure

2>Powerful anti-corrosion,durable and long working life

3>Beautiful appearance,bright surface

4>No dirt-rain-snow deposit,automatic cleaning,easy maintenance

5>Good ventilation,day-lighting,heat-dispersing,resistant to sliding and explosion.

6>Easy installation and disassembly

Remark

We have the automatic machine to make steel grating with largest production capability and high production speed

guttage steel grating inrtroduction

guttage steel grating is made of general carbon bearing bars, stainless steel ,brass sheets,aluminum sheetsof certain size by such operation slotting(trepanning)----spicing----welding finishing, with features of being light weight, high strength, anti-corrosin,free maintance and attractive in appearance, they are widely applied in civil engineering areas like civilian and commercial constructions, theaters,subways,and city constructions.

They can be used in suspended ceilings,interior and exterior decoration and renovation ,platform walkway,airvent window,billboard,andcover board

Installation of steel grating:

1.Welding & using saddle clips are two ways for installation of grating. The welding is suitable for those places where there is no need to move or dismental,for instance,the flooring around the machines. However,using saddle clips are featuring in easy installation & saving zinc layer.

2.Regarding welding installation, angle wolding would used at the first bearing bar of every corner,which the welding length is no less than 20mm,&the height is no less than 3mm.

3.Saddle clip composed of a top plate,a hold down & a M8 bolt, is suitable for all kinds of steel gratings installation.

4.Regarding saddle clip installation, at laest four sets of saddle clips would be used in one pc grating.It would be better using more in the staddle for those gratings with a bigger span.

Specification table of steel grating

No | Item | Description |

1 | Bearing bar | 25x3,25x4,30x3,30x4,30x5,32x5,40x5,50x5,.....75x10mm |

2 | Bearing bar pitch | 12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3, 34.3, 35, 40, 41, 60mm. US standard: 1"x3/16", 1 1/4"x3/16", 1 1/2"x3/16", 1"x 1/4", 1 1/4"x 1/4", 1 1/2"x 1/4" etc. |

3 | Cross bar pitch | 38,50,76,100,101.6mm |

4 | Material | Q235,A36,SS304 |

5 | Surface treatment | Black, hot dipped galvanized, paint |

6 | Thickness | Thickness≥3mm, depth ≥19mm |

7 | Standard | China: YB/T 4001.1-2007 |

USA: ANSI/NAAMM(MBG531-88) | ||

UK: BS4592-1987 | ||

Australia: AS1657-1985 |

Our Services

Our after-sales service start immediately after signing the contract!

1.No matter FOB or CIF the price term is , we would try our best to find a lowest freight cost for customers' reference.

2.The third-party inspection always get real and true data from us and we will send production photos to customers if there is no inspection.

3.Do our best to help customer arrange the shipment and customs clearance.

4.Installation ,maintenance and repair instructions with full informations.

5.3-8 years warranty depends to different products.

6.Accept Changing or Refunding if the products can not be installed rightly.