Powder Micronizer Eddy jet mill

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | D/P, T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Sichuan |

Company Profile

| Location: | Chengdu, Sichuan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | JSDLLV |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | JSDL |

| application: | for all industry |

| condition: | new |

| warranty: | 1 year |

| After-sale service:: | For whole using life |

| Test&Installation:: | For whole using life |

| Spare parts supply:: | For whole using life |

| moq: | 1 set |

| Production Capacity: | 100 sets per month |

| Packing: | wooden packaging |

| Delivery Date: | within 45 working days |

Product Description

Powder Micronizer Eddy jet mill

How it works:

When materials enter the jet mill from the feed inlet port, the machine will start working under high pressure airflow and then materials will crash violently and break into pieces. After selected by pulverizer, fine one will get in dust collector while coarse one will return to jet mill for grinding again. When electromagnetic pulse strikes the filter-bag, fine one will come out from the discharge port.

Characteristics:

Eddy jet mill is an advanced equipment for ultrafine powder processing, which is recently researched and developed by our company. After many years' research and experiment, this product is characterized by the followings:

1, It can adopt the best parameters according to different materials' characteristics.

Energy consumption is less than fluidized bed jet mill by over 10% and less than horizontal jet mill by over 30%.

2. It adopts special flow field simulation and calculation, which can effectively disperse agglomerates.

3. It can accurately control the size distribution of processing materials, even to the size distribution of d97=3~100um. Besides, it can keep high efficiency on processing products of different size distribution.

4. Special jet and classification flow technology are specially fit for the processing of adhensive materials, which can satisfy the demands on the processing of adhensive materials in market.

5. It is easy to clean as there will be no materials left in equipment.

Technical parameter:

specifications and models | Max feed size

| Discharging size (um) | Production capacity(kg/h) | Installed power (kw) | air consumption (m3/min) |

JSDLV-36A | <3 | 2-90um | 50-360 | 40.3-41 | 6 |

JSDLV-120A | <3 | 2-90um | 300-1200 | 134-154 | 20 |

JSDLV-240A | <3 | 2-90um | 600-2500 | 268-311 | 40 |

JSDLV-480A | <3 | 2-90um | 1200-6000 | 520-750 | 80 |

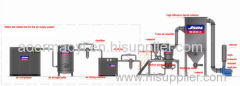

Flow sheet: