Airflow mill/integer milling machine for Silicon mental

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 1 |

| Place of Origin: | Sichuan |

Company Profile

| Location: | Chengdu, Sichuan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Type: | Others |

| Certification: | CE |

| Brand Name: | JSDL |

| function: | integer mill |

| fied use: | industry |

| material: | stainless steel |

| OEM: | available |

| private lable: | available |

| working theory: | Airflow mill |

| Production Capacity: | 1 |

| Packing: | wooden package |

| Delivery Date: | within 1 month |

Product Description

Silicon mental dedicated integer mill

Operating principle

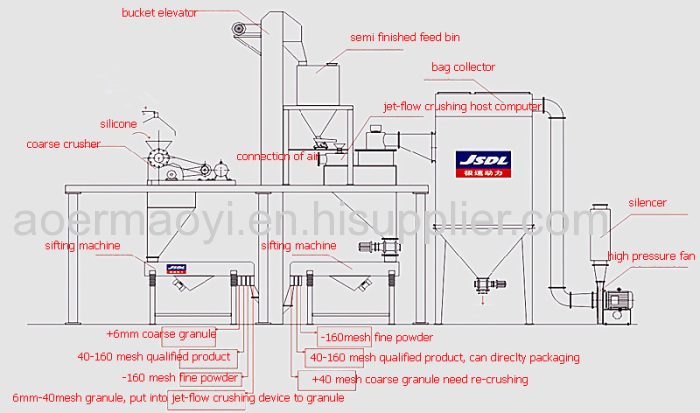

Large bulk material like marble through the crusher to get the desired particle size, next been sent to storage hopper by the elevator, and then the feeder will evenly and quantity to feed into the host grinding chamber to grinding. After grinding, the powder goes along with the airflow and put into powder concentrator. Qualified powder will be collected by cyclone collector, and discharged by powder valve to be the finished powder. This airflow system is under a closed recycle situation, and the entire airflow is in a state of positive and negative pressure circulating. Due to the material in grinding mill contains some water, the heat will lead to the gas evaporation and the airflow will be changed. At the same time there will be some external air absorbed into the system for pipe joints not sealed well. So this increased the air volume, while it will be balance by adjust the exhaust pipe between the fan and host. Excess gas will go into bag dust collector, the powder within the gas will be collected, and the gas will be discharged.

Features:

1. It takes small footprint, has high-grade precision, low wear, and long service life. And the structure is more reasonable.

2. Based on the original host, this mill had been innovative designed, and the product size can be adjusted according to user's requirements.

3. The host has a long service life, so this ensuring that the clean of lubricant oil inside the bearing pad. And it improves the shaft and bushing durability, the service life will be one times longer than conventional mill.

4. Low maintenance, reliable operation, and strong abrasion resistance, it is suit for superhard pure material's classification.

Sketch map:

Factory picture:

Certificate:

service we can supply:

SUPPORT

We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience.

After-sales service support

After we signed the purchase contract and have a certain reputation guarantee, we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on, in order to provide you the perfect goods trading services, until the product you purchased properly to your hands.

We will send a professional and high levels installation engineer team at the same time the product properly to the destination, in order to supply you a full range of products installation services. For some typical problems, our rigorous installed engineers also will do some certain installation debugging training, etc.

Technological support

JSDL has been largely adopting new technologies, new techniques and high-tech equipments. And JSDL also has strict and effective quality control system.

JSDL insists on providing clients with overall solutions from equipment recommendation to debugging and installation, worker training, technical support and maintenance.

contact information:

contact person: caroline

tele/fax: 0086-28-61318297

skype: wanghongyu2505