Fluidized bed jet mill

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Sichuan |

Company Profile

| Location: | Chengdu, Sichuan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | LHC |

|---|---|

| Means of Transport: | Ocean |

| warranty: | 1 year |

| condition: | new |

| After-sale service:: | For whole using life |

| application: | all of material |

| mill: | jet mill |

| raw material: | steel |

| Spare parts supply:: | For whole using life |

| moq: | 1 set |

| Test&Installation:: | For whole using life |

| Max feed size: | under 3mm |

| Production Capacity: | 100 sets per month |

| Packing: | wooden packaging |

| Delivery Date: | within 45 working days |

Product Description

Fluidized bed jet mill LHC

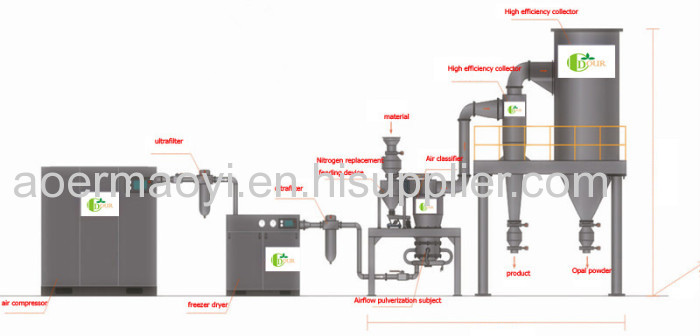

Working principle:

The compressed air after freezing, filtering, drying, through the nozzle formed supersonic airflow into the crushing chamber, let the raw material into fluidization, accelerated material be confluence in the whole nozzle jet stream, produced strong collision, friction, shear then achieve particles ultrafine grinding. Crushed material will be transport to the impeller grade area by rising gas, via grading wheel of centrifugal force and air pumping force, to achieve the separation of powder and coarse powder according to its own gravity to return the crushing chamber to re-crushing, qualified powder along with air flow into the cyclone collector, fine dust collected by the bag dust removal device, the purified gas will be induced by draft fan.

Flow sheet:

The characteristics of equipment:

1 particle acceleration technology breakthrough, greatly improving the crushing efficiency, reduce energy consumption

2 narrow particle size distribution and no large particles

3 materials collide with each other for grinding, wear small, almost no iron pollution

4 in the grinding process, due to the rapid expansion of the air flow and air temperature is reduced, processing and also suitable for heat sensitive materials with low melting point.

5 can perform several kinds of material mixing and crushing

6Compact structure, composite structure, variable, multi use of one machine

7 operations in sealed negative pressure, no environmental pollution

8 easy to operate, the noise is small (less than 85Dba)

Application:

suitable for all kinds of material

Technical parameters:

Model | gas consumption | max feed size

| Discharging size | Produced capacity | installed power | |

JSDL-LHC6 | 1m3/min | <3mm | 1-100um | 0.4-5kg/h | 6-8kw | |

JSDL-LHC18 | 3 m3/min | <3mm | 1-100um | 5-50kg/h | 20-27ke | |

JSDL-LHC36 | 6 m3/min | <3mm | 1-100um | 8-200kg/h | 25-48kw | |

JSDL-LHC120 | 20 m3/min | <3mm | 1-100um | 60-800kg/h | 100-150kw | |

JSDL-LHC240 | 40 m3/min | <3mm | 1-100um | 80-1000kg/h | 200-300kw | |

Factory picture:

Patent certificate:

service we can supply:

SUPPORT

We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience.

After-sales service support

After we signed the purchase contract and have a certain reputation guarantee, we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on, in order to provide you the perfect goods trading services, until the product you purchased properly to your hands.

We will send a professional and high levels installation engineer team at the same time the product properly to the destination, in order to supply you a full range of products installation services. For some typical problems, our rigorous installed engineers also will do some certain installation debugging training, etc.

Technological support

JSDL has been largely adopting new technologies, new techniques and high-tech equipments. And JSDL also has strict and effective quality control system.

JSDL insists on providing clients with overall solutions from equipment recommendation to debugging and installation, worker training, technical support and maintenance.

contact information:

contact person: catherine

tele/fax: 0086-28-61318297

skype: dandelionzoe