Titanium alloy plate BT14 material:BT14(Ti-4.5Al-3Mo-1v)

| Min. Order: | 100 Kilogram |

|---|---|

| Trade Term: | FOB,CIF,DDP,EXW |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 10000kgs |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Baoji, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | BT14 Plate |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | PELIFLY |

| titanium alloy: | sandblasting surface |

| Ti 4.5Al 3Mo 1V: | best quality |

| no crackle stain: | qualified chemical composition and mechianical property |

| material:BT14(Ti-4.5Al-3Mo-1v): | EN10204 3.1 certificate will be supplied with goods |

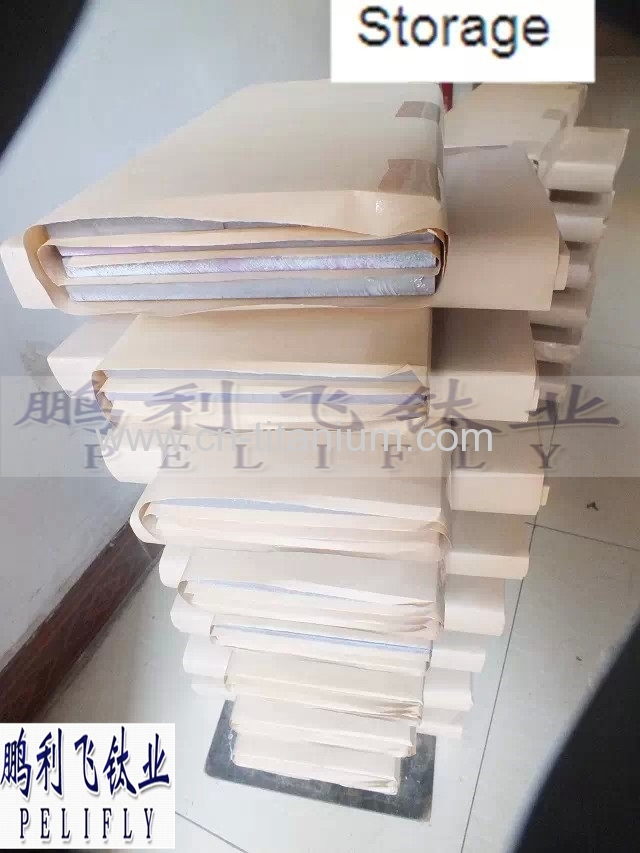

| wooden case packaged: | in stock |

| Production Capacity: | 10000kgs |

| Packing: | wooden case outside+ plastic bag inside |

| Delivery Date: | in stock or 30days |

Product Description

BT14 (Ti - 4.5 - Al - 3 mo - 1 v) titanium alloy is the former Soviet union institute of aviation materials developed in the late 1950 s a martensite can strengthen the alpha + beta titanium alloy heat treatment. In the United States also have similar to the alloy composition of al alloy RMI - 4-3 mo - 1 v (Ti - 431), mainly for the production of sheet metal. BT14 titanium alloy is a kind of titanium alloy with high strength and high tenacity, by strengthening heat treatment to its ultimate strength can reach 1100 mpa, general annealing conditions, its strength can reach about 850 mpa, and has good welding performance and process performance, can be processed into forgings, bar, pipe, plate, sheet. Available for work under 150 ~ 500 ℃ of mechanical parts and components, pressure tanks, etc.

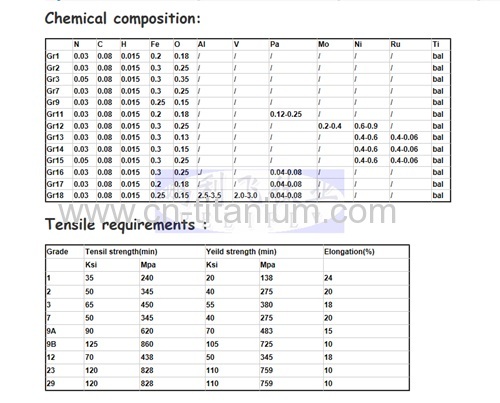

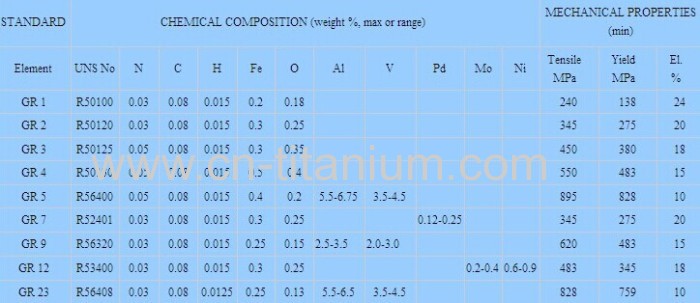

Chemical Compositon

Element | Chemical Composition,% | |||||||||

Gr1 | Gr2 | Gr3 | Gr4 | Gr5 | Gr7 | Gr9 | Gr11 | Gr12 | Gr23 | |

N max | 0.03 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.05 |

C max | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

H max | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.0125 |

Fe max | 0.2 | 0.3 | 0.3 | 0.5 | 0.4 | 0.30 | 0.25 | 0.2 | 0.3 | 0.25 |

O max | 0.18 | 0.25 | 0.35 | 0.4 | 0.2 | 0.25 | 0.15 | 0.18 | 0.25 | 0.13 |

Al max | / | / | / | / | 5.5~6.75 | / | 2.5~3.5 | / | / | 5.5~6.5 |

V max | / | / | / | / | 3.5~4.5 | / | 2.0~3.0 | / | / | / |

Pd | / | / | / | / | / | 0.12~0.25 | / |

0.12~0.25

| / | / |

Mechanical Properties

grade | Tensil strength(min) | Yeild strength(min) | Elongation (%) | ||

ksi | MPa | ksi | MPa | ||

1 | 35 | 240 | 20 | 138 | 24 |

2 | 50 | 345 | 40 | 275 | 20 |

5 | 130 | 895 | 120 | 828 | 10 |

7 | 50 | 345 | 40 | 275 | 20 |

9A/B | 90 | 620 | 70 | 438 | 10/15 |

12 | 70 | 438 | 50 | 345 | 18 |

Titanium alloy plate

Titanium alloy plate

material:BT14(Ti-4.5Al-3Mo-1v)

thickness10mm

width: 185mm lenght : 405mm