processing machinery from color sorter factory

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 35 sets per month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | CCD Color Sorter For Food Processing |

Product Detail

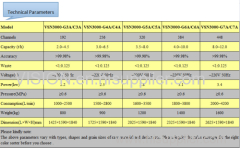

| Model No.: | VSN3000-G8A |

|---|---|

| Means of Transport: | Ocean |

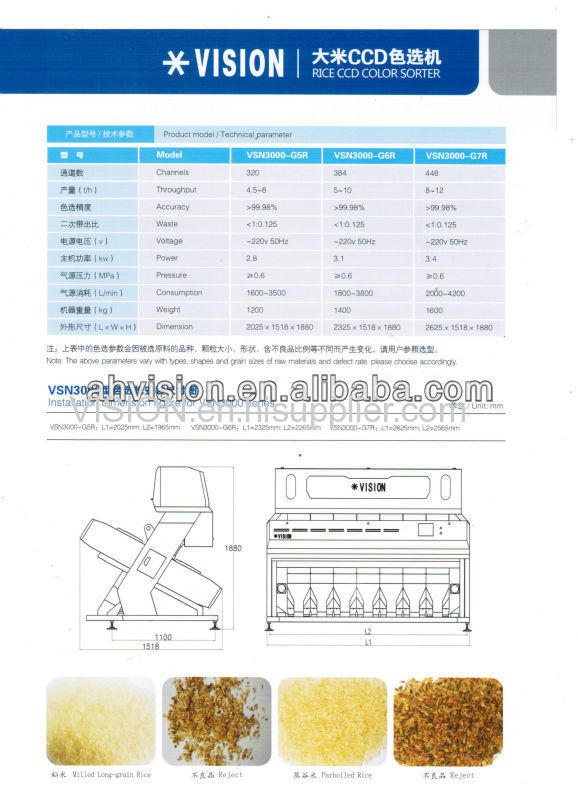

| Processing Types: | Rice |

| Processing: | Sorting Machine |

| Brand Name: | VISION |

| channels: | 512 |

| size: | 2925*1590*1840 |

| weight: | 1800kgs |

| voltage: | ~220V 50Hz |

| waste: | 1 : 0.125 |

| Accuracy: | 99.98% |

| application materials:: | rice,grains,seeds,pea,beans,coffee,nuts,tea,dry fruits,recyclable goods |

| certificates: | CE,ISO9001 |

| Warrenty: | One Year |

| Production Capacity: | 35 sets per month |

| Packing: | standard wooden box |

| Delivery Date: | 10-20 days after order confirmed |

Product Description

Factory View:

Description:

1. The color sorter uses 2048 high performances CCD sensors with resolution up 0.02mm².

2. The sorter adopts high quality special industrial lenses designed and manufactured for color sorting.

3. The high speed FPGA technology signal processor with fast detection and high identification rate.

4. Master control system adopts ARM highend embedded processor, and effectively enhances and control speed and color selection precision.

5. Overall unit adopts intelligent closed-loop control.

6. The operation interface adopts industrial grade 7inch TFT contact screen and features simple parameters setting and esay operation.

7. High speed air value is used to ensure quick response, low power consumption and long service life.

8. Sorters use intelligent temperature and air pressure control technology in order to ensure the best operative mode for the whole machine.

9. Failure alarm automation and modular construction makes easy repair.

Our Advantages:

1.Low waste

2.Low consumption

3.High accuracy

4.High throughput

5.Have our own patented valve

6.Superb After-sale Service

7.Professional Technical Guidance

8.High Quality Imported Parts

9.Self checking system2048 CCD camera and photo processing technology

After sales services:

VISION optical sorters come with clear instructions on how to install them for best performance.

After installation, our service engineer will help you setup the machine and provide instructions on how to run it.

Pre-settings help to quickly change between products and achieve good quality sorting results.

VISION offers trainings to your production manager and for your operator to get a deeper understanding of the principles of optical sorting, what happens inside the machine and how to set and operate it.

Practical exercises in our premises build familiarity and confidence to work with the VISION optical sorters to ensure your staff will make best use of your investment.

Business Cooperation :

Important parts:

Processing effect:

Welcome to visit our factory!