high quality CCD color sorter for food processing machinery

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 35 sets per month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | CCD Color Sorter For Food Processing |

Product Detail

| Model No.: | G7A |

|---|---|

| Means of Transport: | Ocean |

| Processing Types: | Snack |

| Processing: | Sorting Machine |

| Brand Name: | Vision |

| rice sorting: | grains sorting |

| beans sorting: | coffee bean sorting |

| nuts sorting: | raisin sorting |

| seeds sorting: | peanut sorting |

| plastic sorting: | dehydrated vegetable sorting |

| tea sorting: | corn sorting |

| Production Capacity: | 35 sets per month |

| Packing: | wooden case |

| Delivery Date: | 20 days after deposit |

Product Description

We are factory, have patent of the key parts--air valve. we design and assembly ourselves. we have good production procedure and quality control institutions.

What we think is: all of our products Represents MADE IN CHINA, we make out good quality machine start from make every small parts perfect.

our color sorter already export to many countries:American, Mexico, Brazil, Peru,Thailand, Cambodia, Indonesia, Vietnam, India, Pakistan, Bangladesh, Sri Lanka, Africa, Egypt, Italy, Poland, Iran, Romania, Burma, Korea, Uzbekistan,and so on.

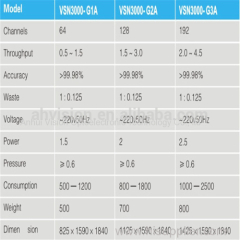

we have some different models to satisfied your different throughput.

Once we confirmed the cooperate relationship, our whole company will try best to serve you, our engineer will fly to your place help you finish assembly and adjust work, our after sales service also wll satisfied you.

the most important,cause we have patent and we design and assembly ourselves. you can pay less buy nice quality machine. if you have any doubts, just come with your raw materials and visit us! see the test yourself!

here under is our products` advantages:

1. CCD Camera: Pixel 2048 high performances CCD sensors with resolution up to 0.02mm2 can ensure fast detection and accuracy.

2. Nikon Lens: from Japan, high quality industrial lenses specially designed for color sorting with

optimized light path to keep each grain of materials perfectly imaged on the sensor.

3. ARM9 chip +FPGA technology:from USA Altera Co.Ltd,Altera company series FPGA technology and high end embedded ARM9 chip with intelligent image processing algorithm ensure the sorter with fast detection ,high identification & accuracy.

4. Pro-face Operation Interface: from Japan,Industrial grade 7inch TFT contact screen with simple parameters setting,easy operation and nice vividness.

5. Air Valve: Our own patented valve with quick response, low power consumption and long service life of 4 billion times. we made it very stickly, from the first,we will chean every small parts,will test every coil. we know every small things can enfluence the rusult,and we just want to make out the best products for our customers.

6. Schneider AC Contactor and Switch: from Germany,High-quality contactor and switch keep good reliability and security.

7. Wide and Clean Chutes/Channels: Thick coating, high quality, special anodizing, decent black chutes enhances cleanness smoothness and abradability.

8. Control system for Overall Unit: Intelligent closedloop control to ensure the reliability of communication and the controlsystem and provides powerful anti-interference .

9. Wind Cooling System: Better cooling system keeps machine longer life service and parts work at suitable temperature.

10. Various Working Mode for Various Seeds.

11.Doubleside detection and easy parameter setting of various working mode to meet different requirements of kinds of seeds like sunflower/white melon/pumpkin/melon seeds with very common application.

12. Concise Modular Structure & Automatic Alarm: Failure alarm automation and modular construction makes repair easy.

14. Business Cooperation: Most part of the machine are from Altera co, Japan Proface,CKD,SMC,Taiwan Meanwell &Schneider.

15. We already sell to this Countries: American, Mexico, Brazil, Peru,Thailand, Cambodia, Indonesia, Vietnam, India, Pakistan, Bangladesh, Sri Lanka, Africa, Egypt, Italy, Poland, Iran, Romania, Burma, Korea, Uzbekistan,and so on.

16. Ejectors: our workers will test all the ejectors one by one, set the largest throughput, keep adjust, till the test result in the qualified range for 5 times. then put it on the vibratory line for 3 hours to make it stable.after this, our customers have no need to adjust themseleves.