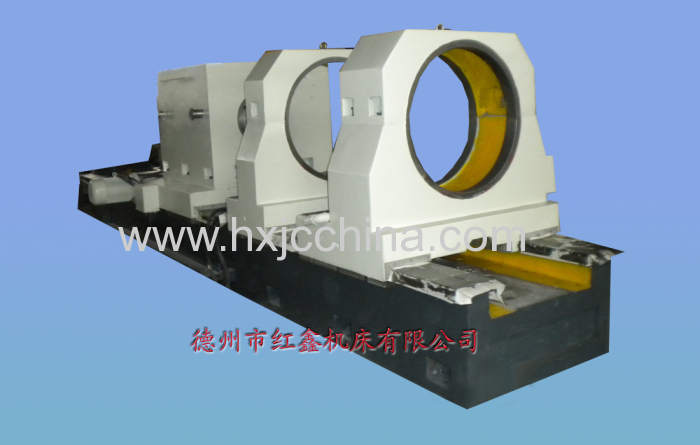

T2160 Deep hole trepanning machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 |

| Place of Origin: | Shandong |

Company Profile

| Location: | Dezhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

| Main Products: | Deep Hole Cutter, Boring Machine |

Product Detail

| Model No.: | HXT2160 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | HongXin |

| Production Capacity: | 10 |

| Packing: | PALLET |

| Delivery Date: | Negotiation |

Product Description

T2160 Deep hole trepanning machine

Products overview

This machine is integrated machine for heavy deep hole producing,max trepan boring hole dia is 600mm,which can make inner trepanning holes.It uses inner chip removal system,cutter rotate and feed.And the cutter and workpiece can rotate at the same time and trepan material out. Machine bed is good rigidity and precision.The spindle speed range is wide. Feeding system is driven by AC servo motor.grant oiler and workpiece fixing is showed by hydraulic instrument.This machine is good in rolling field.

Features

1,bed: it is double square rail,guild rail width is 1250mm,workpiece bed is T style,and it is HT300 cast iron.it is precipitation heat treatment.

2,boring rod box:speed range is 16-26r/min,box is made by HT300 cast iron.it is precipitation heat treatment.

3,feeding:AC servo motor+gearbox+Tr100x16 lead screw,5-300mm/min stepless speed regulation

4,cutting fluid: two sets of pumps which can offer two kinds of flow(300L/min and 600L/min),and it can be used as cooler.

5,trepanning support:it is two tiles on top and bottom,and it is easy to change.Material is HT200, precipitation heat treatment.

6,electrical control system:it has electric control cabinet,AC servo driving device and electric control system.

Main technical specification and skills

specifications | Technical data |

T2160 | |

Sets of dia | Ø300-600mm |

Sets the max depth of holes | 6000mm |

Height from spindle center to bed | 650mm |

Spindle dia drill pipe box | Ø120mm |

Range of spindle bore | 16-26r/min(3 steps) |

Taper of spindle bore | 140mm,1:20 |

Feed speed range(infinite) | 5-300mm/min(stepless) |

Workpiece clamped dia range | Ø600-ø1200mm |

Carriage rapid-moving speed | 2m/min |

Rated pressure for cooling system | 0.36Mpa |

Main motor power | 45KW,n=1440r/min |

Feed motor power | 5.5 AC servo |

Carriage rapid motor power | 5.5KW |

Drill motor power box | 45KW |

Cool pump motor power | 7.5KWX2 N=960r/min |

Flow of cooling system | 300/600L/min |