85mm high torque 3 phase hybrid stepper motors anti - rust shaft

| Min. Order: | 100 Pack/Packs |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 2000 pcs/M |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Changzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | 85HS |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Stepper DC Motors |

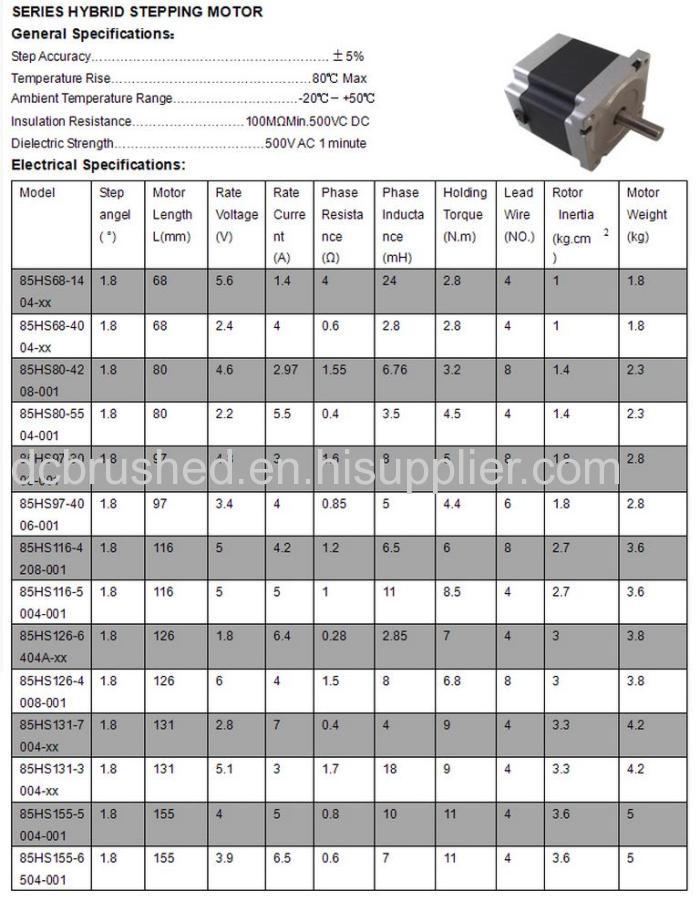

| Step Angle: | 1.8deg |

| Holding Torque: | 2.8-11NM |

| Rated Voltage: | 1.8-5.6VDC |

| Motor Body Length: | 68-155mm |

| Motor Body Size: | 86mm |

| Endcap: | Zinc die cast |

| Housings: | Paint finish |

| Bearing: | NMB or SKF ball bearings |

| Applications: | adhesive dispensing equipment, plastic dropping machines, coil winding machines as well as diamond grinding machines. |

| Production Capacity: | 2000 pcs/M |

| Packing: | Cartons |

| Delivery Date: | 30 DAYS |

Product Description

85mm high torque 3 phase hybrid stepper motors anti - rust shaft

Well machine-turned front and rear endbells with surface-treatment to well endure the extreme working conditions.

The stator lamination stacks are powder-coated in black for anti-rust and anti-moisture performance.

Both rotor and stator laminations are formed by high-precision and auto-stacking punching machines to fundamentally improve the motor performance in reliability as well as in step angle accuracy.

The motor body length is flexible from 68mm to 155mm to allow the application designer more scientific freedom to choose the specific holding torque for his or her end applications.

The hybrid stepper motors are having a wide range of holding torques varying from 2.8N.m to 11N.m, which also can be slightly changed for your OEM designs.

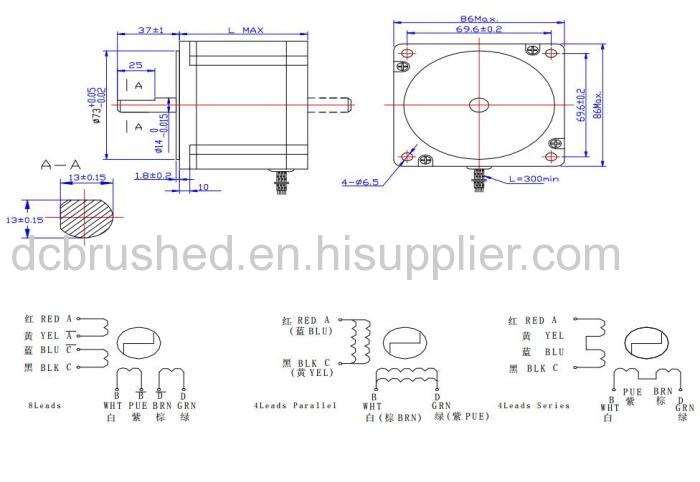

Currently, 4-lead, 6-lead and 8-lead of winding options are available to make the hybrid stepper motors positvely match with different applications among all walks of life.

Applications:

They are widely applied to adhesive dispensing equipment, plastic dropping machines, coil winding machines as well as diamond grinding machines.

Specifications: