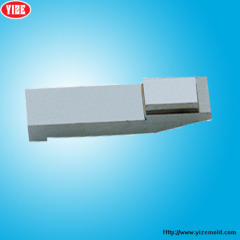

Ejector Pin for Moulds

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, T/T |

| Supply Ability: | 100000 pcs per month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Spare Parts For Moulds |

Product Detail

| Means of Transport: | Air |

|---|---|

| Product: | Vehicle Mould |

| Product Material: | Metal |

| Shaping Mode: | Preform Mould |

| Brand Name: | SR |

| Production Capacity: | 100000 pcs per month |

| Packing: | indivial package |

| Delivery Date: | 3-5 days |

Product Description

Product's name: ejector sleeve pin;

Matarial: SKD61, 1.2344, H13,

Heatment: Nitrided;

Hardness: Inner HRC41-44;

Grinding Precision: 0.001mm;

EDM Precision: 0.002mm;

Surface Roughness: Ra 0.025

Vacuum Heat Treated Nitrogenization Ejector Sleeve Core Pin Insert Sets for Plastic Mold Components

Material: SKD61 Hardness: 56-58HRC

Heat Treatment: Vacuum

Process: Nitrogenization

Concentricity: 0.002mm

Tolerance: Within 0.002mm or as clients' requests

Roughness:Ra0.025

Standard: JIS, DIN, AISI (Custom Made)

Application: Moulds

Description:

1. Made from wear resistant, durable and long lasting hardened SKD61 materials.

2. Super glossy finish and great hardness vacumm heat treated ejector sleeve sets.

3. Excellent performance and close tolerance nitrogenization sleeve core pin insert sets.

4. Consistent quality control and fast delivery.

5.More products can be produced according to "MISUMI","PUNCH", "DANLY", "DME", "HASCO", "TOHATSU", "FIBRO", "AGATHON", "STRACK", "PEDROTTI", "RAYMOND", "FUTABA","SANKYO", "PROGRESSIVE", "RABOURDIN", etc., or as customers' drawings.