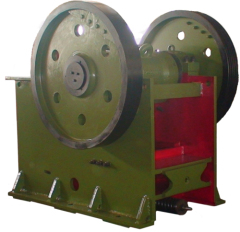

Rock Crusher maisheng rock crusher

| Place of Origin: | Henan |

|---|

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Drying Equipment, Beneficiation Equipment, Sand Making Equipment, Crushing Equipment |

Product Description

Application of Rock Crusher:

Rock crusher (jaw-breaking for short, PE new jaw-breaking), widely used in mining, smelting, building material, highway, railway, water conservancy and chemical industry and many other departments. Jaw crusher can crush different kinds of materials which the compressive strength is not more than 320MPa, is the first choice of primary crushing equipment.

Rock Crusher:http://www.ms-machinery.com/product/rock-poineer-double-toggle-jaw-stone-crusher.html

The Main Features of Rock Crusher:

1)High capacity

2)High reliability

3)Adjustable for easy wear parts

4)Over-loading protection

5)Simple structure and easy to operate

6)Easy replacement of wear and spare parts

7)Energy-saving equipment: Stand-alone energy-saving 15% ~ 30%, the system energy-saving more than doubled

8)low noise and less dust

Working Principle and Structure of Rock Crusher:

The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves. So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet.

Technical Parameter of Rock Crusher:

Model | Technical specification | Power(kw) | Overall Dimensions(mm) | Weight | |||

Max. Feeding | Adjustment scopes(mm) | Capacity | Rotating speed of main shaft(r/min) | ||||

PEF150×250 | 125 | 10-40 | 1-3 | 285 | 7.5 | 922×745×933 | 550 |

PEF200×300 | 165 | 20-70 | 2-8 | 265 | 11 | 1056×1100×1120 | 680 |

PEF250×400 | 210 | 20-80 | 5-20 | 310 | 18.5 | 1108×1142×1392 | 2600 |

PEF400×600 | 340 | 40-90 | 10-40 | 275 | 30 | 1700×1732×1392 | 6200 |

PEF350×750 | 290 | 30-55 | 20-50 | 300 | 37 | 1900×1806×1808 | 7900 |

PEF500×750 | 425 | 50-100 | 34-68 | 275 | 55 | 2050×1860×2145 | 10320 |

PEF600×900 | 480 | 75-200 | 40-120 | 255 | 75 | 2792×2168×2250 | 16600 |

PEF750×1060 | 630 | 80-200 | 80-160 | 250 | 90 | 4180×2560×3070 | 27530 |

PEF900×1200 | 750 | 100-200 | 110-200 | 250 | 110 | 5200×2900×3500 | 46000 |

PEF1200×1500 | 1020 | 150-300 | 220-400 | 180 | 160 | 4200×3300×3500 | 106000 |

PEX150×750 | 125 | 10-40 | 5-15 | 300 | 15 | 1220×1480×1180 | 2800 |

PEX250×1000 | 210 | 15-55 | 10-32 | 300 | 37 | 1580×1992×1380 | 6350 |

PEX250×1200 | 210 | 15-60 | 12-38 | 300 | 37 | 1530×2192×1380 | 7800 |

PEX300×1300 | 250 | 20-90 | 16-65 | 300 | 55 | 1930×2400×1747 | 1060 |