Tundish Nozzle for continuous casting

| Payment Terms: | L/C, D/P, T/T |

|---|---|

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Series Of Sub-entry Nozzles, Monolithic Stoppers, Tundish Upper Nozzles, Ladle Shrouds, Graphite Stoppers And Nozzles Fo |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | Sinosea |

Product Description

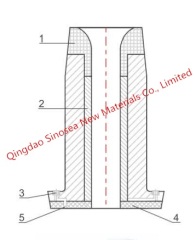

Tundish Nozzle

The application of the product makes the exchange of SEN come true, extends service life of tundish and reduces production cost. The core of tundish nozzle is sintered zirconia products, where whole inlay making is used. So, it has better anti-corrosion and anti-erosion property, which extends service time of tundish and better cooperation with stoppers. Therefore it can meet different continuous casting level requests

※High-Al coatings with perfect anti-thermal shock property.

※The body adopts sintered zirconia materials with perfect anti-corrosion and anti-erosion property

※The end part adopts stable Zirconia product, better anti-erosion property, and also easy for flow control.

Specification

Items | Body | Bowl part | ||

Alumina-Graphite | Alumina-Graphite | Magnesia-Graphite | ||

Chemical Composition (%) | Al2O3 | ≥50 | ≥75 | --- |

C+SiC | ≥25 | --- | ≥75 | |

ZrO2 | --- | ≥10 | ≥10 | |

Bulk Density(g/cm3) | ≥2.45 | ≥2.75 | ≥2.70 | |

Apparent Porosity(%) | ≤18 | ≤16 | ≤16 | |

Cold Crushing Strength(MPa) | ≥20 | ≥25 | ≥20 | |

Modulus of Rupture(MPa) | ≥7 | ≥7.0 | ≥5.0 | |

Thermal Shock Resistance(sequence) | ≥5 | ≥5 | ||