Photovoltaic solar interconnector busbar tabbing wire for PV solar cell panel

| Min. Order: | 10 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 3T one day |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | 60Sn40Pb |

|---|---|

| Means of Transport: | Ocean, Air |

| Application: | Solar Thermal |

| Type: | Flat Panel |

| Pipe Material: | Copper |

| Brand Name: | DK |

| SIZE: | 5*0.2MM |

| Materials: | Copper wire coated by tin |

| Type: | soldering ribbon |

| Customized: | Customized is available |

| Production Capacity: | 3T one day |

| Packing: | paper carton with pallet |

| Delivery Date: | 3-15 days after received deposite |

Product Description

PV ribbon Photovoltaic solar wire busbar tabbing wire for PV solar cells module panel is composed of Copper and coating alloys, and divided into Tabbing Ribbon and Bus bar ribbon.

Solar cell soldering ribbon with good quality

PV solar ribbon /solar wire is composed of Copper and coating alloys, and divided into Tabbing Ribbon and Bus bar ribbon.

Solar cell soldering ribbon with good quality

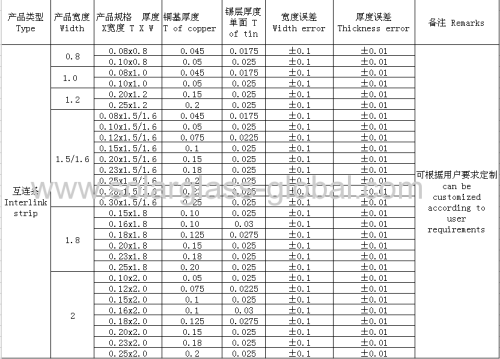

Automatic welding interlink strip

1.Environmental protection PV Ribbon has already passed SGS test with Europe Union RoHS directive standards.

2.Copper:oxygen-free copper wire planish,

Contain copper quantity≥99.97%,Conductivity≥100%

3.Copper electrical resistivity:Oxygen-free copper≤0.0165Ωmm²/m

T2 copper≤0.0172Ωmm²/m

4.Component:63%Sn37%Pb,60%Sn40%Pb (TM-A)

96.5%Sn3.0%Ag0.5%Cu,99%Sn1%Ag (TM-B)

62%Sn36%Pb2%Ag (TM-C)

5.Solder tin melting point:179~217℃

6.Tensile strength:≥200N/mm²

7.Extensibility:≥25%

8.According to customer requirements,we can provide different chemical coating and different sizes of products

Hand welding interlink strip/bus bar

1.Environmental protection PV Ribbon has already passed SGS test with Europe Union RoHS directive standards.

2.Copper:oxygen-free copper wire planish,

Contain copper quantity≥99.97%,Conductivity≥100%

3.Copper electrical resistivity: Oxygen-free copper≤0.0165Ωmm²/m

T2 copper≤0.0172Ωmm²/m

4.Component:63%Sn37%Pb,60%Sn40%Pb (TM-A)

96.5%Sn3.0%Ag0.5%Cu,99%Sn1%Ag (TM-B)

62%Sn36%Pb2%Ag (TM-C)

5.Solder tin melting point:179~217℃

6.Tensile strength:≥200N/mm²

7.Extensibility:≥20%

8.According to customer requirements, we can provide different chemical coating and different sizes of products