304 Stainless Steel Welded Pipes China manufacturer

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50000 tons per year |

| Place of Origin: | Shanxi |

Company Profile

| Location: | Jinzhong, Shanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Stainless Steel Pipes |

Product Detail

| Model No.: | DMD |

|---|---|

| Means of Transport: | Ocean, Land |

| Outside Diameter: | 355.6mm |

| Wall Thickness: | 6mm |

| Length: | random-12m Max |

| Grade: | TP304/304L/316/316L |

| Application: | convey fluid and gas |

| Feature: | long service life |

| Standard: | GB,ASTM.JIS,DIN,EN |

| End Situation: | plain ends,bevel ends |

| Delivery Condition: | pickling,annealing |

| Performance: | corrosion resistance,high temperature corrosion |

| Production Capacity: | 50000 tons per year |

| Packing: | according to the customer's requirements |

| Delivery Date: | according to the order quantity |

Product Description

Shanxi Diamond Stainless Steel Technology Co.,Ltd.

Specification

Commodity Name | Stainless Steel Welded Pipes |

TP304/304L/316/316L/321 | |

Outside Diameter | 159-3048mm The specifications can be produced according to your specific inquiry |

Nominal Wall Thickness | 3-40mm |

Standard | GB,ASTM,JIS,DIN,EN ASTM A312/A554/A249/A269/A270/A358/A778 |

Application | Natural Gas, Electric Power, Nuclear Power,Petrochemical Engineering |

Payment terms | T/T,L/C at sight |

Performance | Corrosion resistance, high temperature and high pressure resistance |

Feature: long service life, energy saving and environmental protection

Advantages: excellent quality, competitive price

Highlights: provide the related products, such as seamless pipes, carbon steel pipe, stainless steel sheets, pipe fittings

Company Information

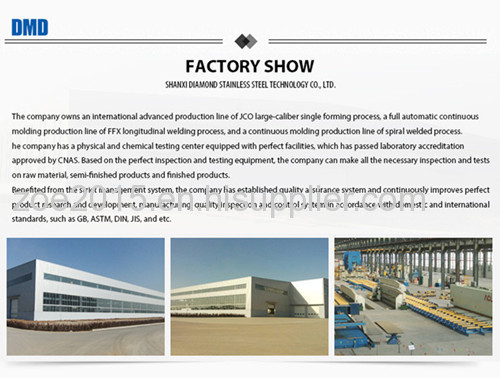

Office Building

Factory Information

Factory Corner

Product Overviews

Production Process

Heat Treatment

Strict Detection

Perfect Quality Control System

1. IQC-Incoming Quality Control

A. Dimension Measurement

B. Chemical Composition

2. IPQC-Input Process Quality Control

A. Quality control of every procedure in production process

B. Non-destructive test: X-ray real time imaging of weld

3. FQC-Final Quality Control

A. Visual Inspection

B. Size or Diameter Measurement

C. Performance Test

Shipping & Packing