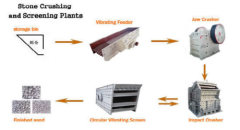

Stone Crushing & Screening Plants

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 t/h to 500 t/h |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Benicifiation Equipment, Sand Making&washing, Production Line, Grinders+mills, Crushers |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Application: | Others |

| Type: | Crusher |

| Brand Name: | VIPEAK |

| capacity: | 50 t/h to 500 t/h |

| Certification: | CE ,ISO9001 , IQNET , GOST |

| After-Sale Service: | Installation and Permanent Maintain |

| Production Capacity: | 50 t/h to 500 t/h |

| Packing: | Containers, export standard |

| Delivery Date: | 20 days |

Product Description

Stone Crushing & Screening Plants

we manufacture various equipments for whole set of stone production line, and provide complete technical support for customers. The whole production line consists of Vibrating Feeder, Jaw Crusher, Impact Crusher, vibrating screen, Belt Conveyor, electric control, etc. We design different production lines ranging 50 t/h to 500 t/h by combining different models of equipments also matching Cone Crusher, deduster, etc. It is widely used for crushing hard limestone, granite, basalt, gravel, metallurgic slag, etc or artificial sand making for hydroelectric power, building material, high way, city construction, etc. Different models of equipments are combined to meet different customers' demands according to different craft requirements.

Process of the Production Line:

Big size stones are transferred to primary crusher through Vibrating Feeder from hopper for first crushing, then the crushed materials are transferred to Impact Crusher through Belt Conveyor for secondary crushing. The crushed materials will be transferred to the vibrating screen, and separated to different sizes. Those aggregate with suitable size will be transferred to the final product pile and those with unsuitable size will be transferred to the Impact Crusher for re-crushing. This forms a closed circuit manifold cycles. The sizes of final products will be graded and separated according to customers' requirements, and the deduster will be attached for the sake of environment protection.

.gif)