Iron casting pipe flange clamp

| Min. Order: | 200 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 1000 mt per month |

| Place of Origin: | Tianjin |

Company Profile

| Location: | Tianjin, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Grey Iron Manhole Cover Manufacturer Casting Parts, Ductile Iron Manhole Cover Manufacturer Casting Parts, Customized Coated Sand Manhole Cover Casting Parts, Black Bitumen Coated Sand Iron Manhole Cover Casting Parts, Ductile Iron Machine Tool Frame OEM |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Brand Name: | ZY |

| Surface Treatment: | Spary paint |

| Materials: | Cast steel |

| Standard: | GB |

| Original of place: | China |

| Cerfication: | ISO9001;2000 |

| MOQ: | One container |

| Production Capacity: | 1000 mt per month |

| Packing: | Wooden carton |

| Delivery Date: | 20 days |

Product Description

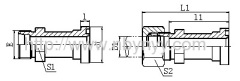

Iron casting pipe flange clamp manufacturer

Specification:

Carbon Steel Flanges Clamps | ||

Flange Material | Carbon steel | ASTM A105. ASTM A350 LF1. LF2, CL1/CL2, A234, S235JRG2, P245GH |

P250GH, P280GHM 16MN, 20MN ,20# | ||

Stainless steel | ASTM A182, F304/304L, F316/316L | |

ASTM A182 A182 F12,F11,F22,F5,F9,F91etc. | ||

Flange Standard | ANSI | Class 150 Flanges-Class 2500 Flanges |

DIN | 6Bar 10Bar 16Bar 25Bar 40Bar | |

JIS | 5K Flanges-20K Flanges | |

UNI | 6Bar 10Bar 16Bar 25Bar 40Bar | |

EN | 6Bar 10Bar 16Bar 25Bar 40Bar | |

Flange TYPE | 1.Welding neck Flange;;; 2.Slip on | |

3.Blind flange4.Long welding neck flange | ||

5.Lap joint flange 6.Socket welding | ||

7.Threaded flange 8.Flat flange | ||

Flange Surface | Anti-rust oil, clear lacquer, Black lacquer, Yellow lacquer, hot-dipped Galvanized, electrical galvanized | |

Connection | Welding, Threaded | |

Technical | Forged, Casting | |

Flange Size | DN10-DN3600 | |

Flange Package | 1.>Standard export packaging (Plywood Case Of Outside,Plastic Cloth Of Inside). 2:As Customers' Requirements | |

Flange Heat Treatment | Normalizing, Annealing, Quenching+Tempering | |

Flange Certificate | TUV,ISO9001:2008;PED97/23/EC,ISO14001:2004,OHSAS18001:2007 | |

Flange Applications | Water works, Shipbuilding industry, Petrochemical & Gas industry, Power industry, Valve industry,and general pipes connecting projects etc. | |

WHAT SERVICE WE OFFER?

We offer you OEM service for casting parts , especially in sand casting.

Sand casting,also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process.Sand casting is relatively cheap and sufficiently refractory even for steel foundry use. In addition to the sand,a suitable bonding agent is mixed or occurs with the sand. The mixture is moistened with water to develop strength and plasticity of the clay and to make the aggregate suitable for molding.The sand is typically contained in a system of frames or mold boxes known a flask. The mold cavities and gate system are created by compacting the sand around models, or patterns, and or carved directly into the sand. Can maintains typical tolerance accuracy within CT12-CT14 standard, with a surface finish of Ra50-100.

CAN WE OFFER CNC CATING PARTS?

Yes, We offer CNC service to make the surface of casting parts as polished & precise as you request.

WHAT KIND OF SURFACE TREATMENT CAN WE GET?

Heat Treatment, shot blasting, sand blasting, machining, polishing, plating, powder coating, anodizing, zinc plated(galvanization,), oxide, etc.

HOW WE MAKE THE PARTS COMPLY TO CUSTOMER'S REQUIREMENT?

Useing our coordinate measuring machine, tensile testing machine, spectrograph and other testing equipments to make all the goods qulified.

HOW CAN WE QUOTE FOR YOU?

As our factory only supply OEM service,Please send us enquiry by email, with all the technical drawings you have, with all of your requirements, such as material grade, tolerance, machining demands, surface treatment,heat treatment, mechanical property requirements, etc. Our specialized engineer will check and quote for you, we would appreciate the opportunity and will respond in 3~5 working days or less.

It is also best if you can provide a sample, we can also quote depends on the sample.