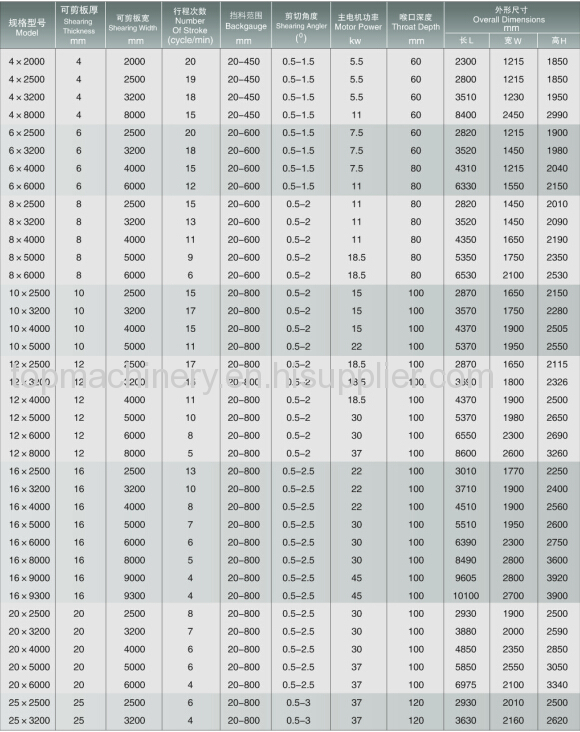

Hydraulic Guillotine Shearing Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 30sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Nantong, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Trading Company |

| Main Products: | Hydraulic Ironworker, Plate Bending Machine, Press Brake, Guillotine, Shearing Machine |

Product Detail

| Model No.: | QC11Y-6x6000 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Hydraulic |

| Certification: | CE |

| Brand Name: | Top Machinery |

| Production Capacity: | 30sets/month |

| Packing: | Covering with PVC plastic, colour cloth, with steel pallet |

| Delivery Date: | 15-25days |

Product Description

Description:

1.Ball roller worktable, rear protection guard via means of 2 light beams

2.Hinged front finger guard with limit switch.

3.ESTUN E10 NC System, LED DRO for back gauge+ mechanical counter

4.2 off adjustable 1.0M suqaring arm with rule and tilting stop + plate supports in between squaring arms

5.Shadow wire+ Shadw light, ball transfers on the table

6.Belt or shaft driven backstop strole from 10mm to 750mm

7.Siemens electric components

8.OMD American Omega valves

9.China famous motors

10.400V/3PH/50Hz+ earth, English/Chinese

Holistic welding structure treated by annealing.

The top rest does the linear motion under the hydraulic cylinder′s drive.

Both the upper and lower blades are rectangular,and the blade clearance can be rapidly adjusted manually or electrically.

Time relay controls shearing stroke and shearing angles are adjusted electrically.

The forward and backward movement of the back gauge is motorized and indicated by a digital display,while fine adjustments are also available.

All major electrical and hydraulic elements are assembled with high grade international brands.

A light alignment device makes shearing much easier and more efficient.

Pneumatic back support is optional.

CNC Machines Only:

CNC system controls ram and back gauge movement.

Blade clearance,shearing angle and shearing length are calculated and controlled automatically by CNC system.