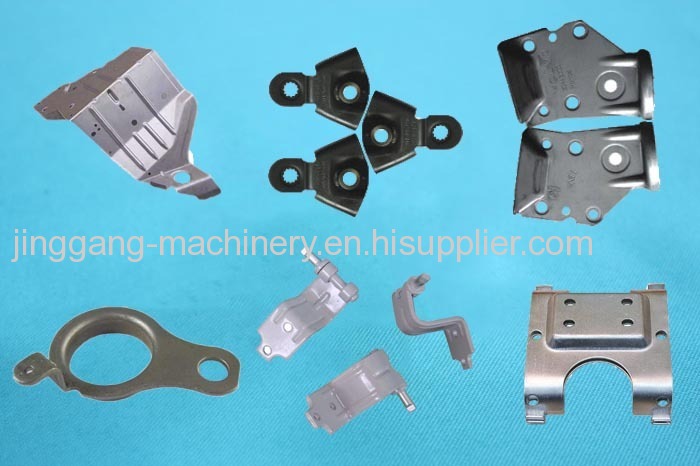

motorcycle parts motorcycle accessories parts for machine

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 20000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | JG-04-0078 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Weight: | 205g |

| Application: | motorcycle parts |

| Material: | aluminium alloy |

| Processing: | pressure casting |

| Surface treatment: | polishing |

| Quality grade: | high quality |

| Grand: | JG |

| Certificate: | TS16949:2009 |

| Color: | nature |

| Production Capacity: | 20000 |

| Packing: | carton, wooden case |

| Delivery Date: | 40 days |

Product Description

Detailed picture for product

Detailed picture for product

Die casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. Die-casting can be done using a cold chamber or hot chamber process.

Process:

Jinggang Machinery offers the integrated services of collection, compression, casting, molds, design, manufacture, pressure casting, and precision finishing. All conform to a rigorous quality control system. Our advanced equipment and strict quality control system ensure excellent quality for foreign customers.

Equipment:

63T, 125T, 160T, 250T, 400T, 630T, 800T, 1000T, 1300T die-casting machines, chemical analysis and mechanical test instruments, Furnace for T1-T6 heat treatment

Material:

Aluminum alloy, zinc alloy; e.g. A356 (G-AlSi7Mg), A360 (G-AlSi10Mg), A380, ADC12, ZnAl4-1, Zn-5,Zn-3 etc.

Application:

Sandblasting, vibration, grinding, low chromium passivation, anodizing, plating, powder coating, polish

Capacity:

Part weight : 0.020-30.00KG Dimensions: up to 950 mm x 700 mm

Surface:

Sandblasting, vibration, grinding, low chromium passivation, anodizing, plating, powder coating, polish.

Stamping parts

Machining parts

Die casting parts

Die casting parts

Forging parts

Other machinery parts

The workshop

The equipments

Our certicificate

Core Values

1. We run transparent pricing.

Our skilled engineers will find out the best solution on your parts.

To contribute to your final products competitive on the market..

2. Quality responsibility

We never compromise with the quality.

We strictly implement Quality Control Procedure on your requirements

We realize quality control in process.

3. Delivery reliability

High flexibility.

Reliability

Problem-solving expertise

.jpg)