Electrified Railway Type Insulator

| Place of Origin: | Hebei |

|---|

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Heat Shrink Termination |

Product Description

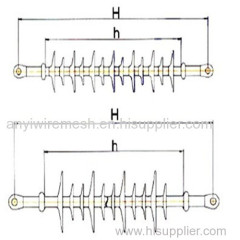

Electrified Railway Type Insulator

Composite railway insulator

Composite railway insulator is suitable for electric railway of complex operation conditions and must effectively prevent flashover accidents and decrease the times of clearance and maintenance, especially in the small railway tunnel. Since composite electrical railway insulator is small volume and light weight, it is widely used to replaced porcelain insulator and glass insulator for railway.

Honor and qualification for composite railway insulator:

1. CRCC certificate: We are one of the first companies of getting the CRCC certificate which proves we have the right to supply composite railway insulator to China railways Corporation and our product is enough qualified to suit the technical requirement of China railway.

2. Appointed enterprise: Our Company is the appointed enterprise by ministry of railways to produce composite electrical railway insulator.

3. Ourselves raw material: we are the first company that all the raw materials are produced by ourselves for composite railway insulator suspension type.

Type of composite railway insulator:

1. Composite railway insulator suspension type: as normal composite suspension insulator, the composite railway suspension insulator is used suspend conductor and use for 33kV and below. The end fitting for composite railway insulator is ball and socket.

2. Composite electrical railway insulator post type: this composite electrical railway insulator post type is used to support conductor and insulating from cross arm just like most of composite insulators.

Processing for composite electrical railway insulator:

1. Design composite electrical railway insulator according to customer requirement

2. Confirm drawing

3. Prepare mould totally in accordance with composite railway insulator drawing

4. Prepare composite insulator end fitting

5. Crimp end fitting onto epoxy reinforced fiber glass core

6. Molding or injection

7. Sheds surface treatment

8. Sample test for composite electrical railway insulator

9. Packing

10. Delivery