Rubber conveyor belt Industrial Rubber belt

| Min. Order: | 1 Meter |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 3000m/day |

| Place of Origin: | Hebei |

Company Profile

| Location: | Baoding, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Frame, Pulley, Conveyor Roller, Conveyor Belt |

Product Detail

| Model No.: | EP100-600,NN,CC |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Belt Conveyor |

| Material: | Polyester |

| Material Feature: | Heat Resistant |

| Brand Name: | SHUNDA or OEM |

| Model Number: | ep100-600 |

| Width: | 400-3000mm |

| thickness: | 3-50mm |

| Rubber Grade: | 8-25mpa |

| Capacity: | :40-1280 t/h |

| Max.Length/Roll: | 300m |

| Strength: | :100N/mm to 630N/mm per ply |

| Certification: | CE, ISO, SGS. |

| Standards: | GB/T7984-2001, DIN22102, BS490, AS1332, RMA, JISK6322, SABS1173 etc |

| Production Capacity: | 3000m/day |

| Packing: | standard export packing |

| Delivery Date: | 7days. |

Product Description

Skype:camilleliu85

Email:camille(at)shundaxj.com

Phone: 86-312-2162686

Application

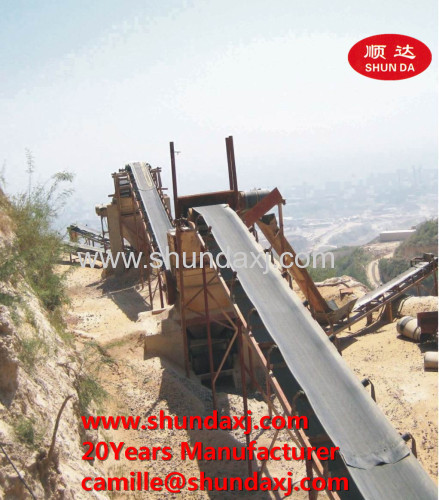

Widely used in coal, mining, metallurgy, ports, electricity, chemical industry transportation of materials. Fire power plants, port facilities, sugar and salt works, mining, iron and steel industry etc.

Our advantage:

· Brand Name:SHUNDA

· Model Number:EP100-EP600

· Width:200-3000mm

· thickness:3mm – 50mm

· Rubber Grade:8Mpa – 25Mpa

· Capacity:40-1280 t/h

· Max.Length/Roll:300 meters

· Strength:100N/mm to 630N/mm per ply

· Certification:CE, ISO, SGS.

· Standards:GB/T7984-2001, DIN22102, BS490, AS1332, RMA, JISK6322, SABS1173 etc

· We already export to more than 30 countries.

· Specialize in this products manufacture more than 19 years

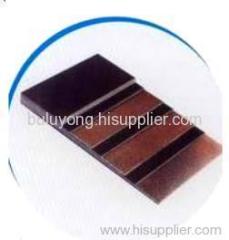

Specification and technical data of multi-ply polyester conveyor belt

Fabric type | Fabric stucture | Fabric | Ply thickness (mm/P) | Strength series(N/mm) | Cover thickness (mm) | Width | Lengthm | ||||||

Warp | Weft | 2ply | 3ply | 4ply | 5ply | 6ply | Upper | Lower | |||||

Polyester | Polyester | polyeater | EP-80 | 0.80 | 160 | 240 | 320 | 400 | 480 | 2.0~8 | 0~4.5 | 400~500 | ≤300 |

EP-100 | 0.80 | 200 | 300 | 400 | 500 | 600 | |||||||

EP-125 | 0.85 | 250 | 375 | 500 | 625 | 750 | |||||||

EP-150 | 0.90 | 300 | 450 | 600 | 750 | 900 | |||||||

EP-160 | 0.90 | 320 | 480 | 640 | 800 | 960 | 500~2500 | ||||||

EP-200 | 1.05 | 400 | 600 | 800 | 1000 | 1200 | |||||||

EP-250 | 1.25 | 500 | 750 | 1000 | 1250 | 1500 | |||||||

EP-300 | 1.35 | 600 | 900 | 1200 | 1500 | 1800 | |||||||

EP-350 | 1.50 | - | 1050 | 1400 | 1750 | 2100 | 600~2500 | ||||||

EP-400 | 1.80 | - | - | 1600 | 2000 | 2400 | 600~2500 | ||||||

EP-500 | 2.00 | - | - | 2000 | 2500 | 3000 | |||||||

Adhesion and elongation of the belt

carcass | Adhesive strength | Elongation | |||

Between plies N/mm | N/mm Between ruber and carcass | Longitudinal | Longitudinal elongationa at reference load % ≤ | ||

Rubber thickness ≤ 1.5mm | Rubber thickness 1.5mm | ||||

EP canvas | ≥ 4.50 | ≥ 3.50 | ≥ 3.50 | 10 | 4.0 |

Cover properties of the belts

Cover grade | Tensile strength | Elongation | Abrasion | Change Rate of tensile strength and elongation after aging | |

Mpa | kgf/cm 2 | % | mm 3 | % | |

Heavy(H) | 24 | 240 | 450 | 120 | -25~+25 |

Medium(M) | 18 | 180 | 400 | 100 | -25~+25 |

Light(L) | 15 | 150 | 350 | 200 | -30~+30 |