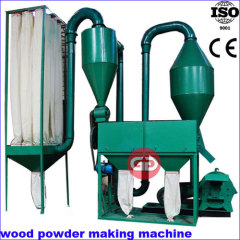

CE approved high performance wood powder making machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T, paypal, WU |

| Supply Ability: | 500 sets/year |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Trading Company, Agent, Distributor/Wholesaler |

| Main Products: | Drum Wood Chipper, Disc Wood Crusher, Shredder, Biomass Pellet Mill, Feed Pellet Machine |

Product Detail

| Model No.: | 500(water cooled) |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product: | wood powder making machine |

| model: | 500(water cooled) |

| Main motor power(kw): | 18.5~22 |

| Drum sieve motor power(kw): | 2.2 |

| Host speed(r/min): | 3300 |

| Capacity(kg/h): | 60~400 |

| Finished size(mesh): | ≤325 |

| Weight(kg): | 1500 |

| Area for machines(m): | 4.5*2*5 |

| Material moisture rate: | <6% |

| Production Capacity: | 500 sets/year |

| Packing: | standard wooden packing |

| Delivery Date: | within 15-25 after receipt of payment/deposit |

Product Description

CE approved high performance wood powder making machine

Standard wood powder machine

Introduction:

Standard wood flour machine is flour machine in the market as a new product that can guarantee the standard rate of finished products, address the inconvenience from uneven distribution of product fineness, the internal preparation of standard stainless steel mesh, mesh arbitrary choice. It's the ideal milling equipment with small footprint, easy assembly, simple operation and no dust pollution.

Applicable scope:

Processing Bamboo powder, shell, herbs, bark,leaves,wheat bran, grinding line, Ma Xuan, rice husk, corncob,straw, starch, grains, shrimp, fish meal, seaweed,dehydrated vegetables, hawthorn, dried ginger, garlic, pumpkin powder, spices, jujube, paper, circuit boards, plastic, chemical raw materials, water products, mica, graphite,Bentonite, perlite,lees, furfural, cake charcoal, activated carbon, fiber Su, Residues, tea, hair, soybean cotton, cowhide, sheepskin, plant root,stem, leaf, flower and fruit, various edible fungi and hundreds of other difficult materials, it's the ideal grinder for chemical, building materials, medicine, health care, culture, food mosquito coils and other industries.(Note:Flammable and explosive materials can not be crushed)

Main advantages:

1.Fine production, high processing technology, double layer body.

(1) The machine could be poured into running water to get the function of cooling.

(2) The machine could be put into a new kind of material to get the function of sound insulation and heat dissipation.

(3) The machine has lower noise and no vibration. It is durable and has high capacity. The efficiency is 50% higher than the traditional machine.

2. The machine could equip with three kinds of cutter blade: 7 model blade, flat blade and centrifugal knife.

3. The machine has fineness analyzer and could control the fineness of the finished products.

4. The machine could crush the materials into different fineness finished products.

Main parameter:

Model | 500(water cooled) | 700(water cooled) | 800(water cooled) | 1000(water cooled) |

Main motor power(kw) | 18.5~22 | 22-30 | 30-37 | 45-55 |

Drum sieve motor power(kw) | 2.2 | 2.2 | 2.2 | 2.2 |

Host speed(r/min) | 3300 | 3300 | 3300 | 2900 |

Capacity(kg/h) | 60~400 | 80-500 | 80-600 | 100-800 |

Finished size(mesh) | ≤325 | ≤325 | ≤325 | ≤325 |

Weight(kg) | 1500 | 2200 | 2600 | 3200 |

Area for machines(m) | 4.5*2*5 | 5*2.5*5 | 5*2.5*5 | 5*2.5*5 |

Material moisture rate | <6% | <6% | <6% | <10% |

Notes | Due to a wide variety of the materials, fineness and capacity is depended on the proportion of the materials | |||

More photos for our wood powder making machine:

More information or competitive price, pls contact us!