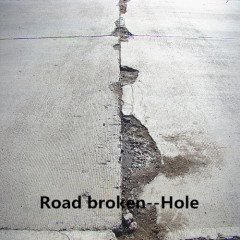

Concrete rapid repair material aiming at concrete pothole manufactured by HUINENG in China

| Min. Order: | 5 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2000 tons one month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Concrete Repaid Repair Materials, Concrete Driveway Crack Repair Materials, Best Concrete Waterproof Repair Mortar, Best Material For Filling Cracks In Concrete Driveway, Bridge Deck Expansion Joint Repair Solution |

Product Detail

| Model No.: | SC |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HUINENG |

| Minimum passing time: | 2-4 hours |

| Initial setting: | 25 min |

| Final setting: | 45 min |

| Compressive strenth: | More than 76 Mpa/28days |

| Certificate: | ISO9001 |

| Means of transportation: | Ocean |

| Color: | Grey |

| Deliver time: | In one week |

| Email: | lovelyfunnyhelen@gmail.com |

| Production Capacity: | 2000 tons one month |

| Packing: | 25kg/ bag |

| Delivery Date: | In one week |

Product Description

Concrete rapid repair material aiming at concrete pothole manufactured by HUINENG in China

1.Product Introduction:

SC type concrete road repair material is developed by Henan Huineng Road And Bridge Technology Co.,Ltd. Which is of rapid repair material for highways, national roads, provincial road and municipal roads,

especially aiming at repair deep desease( cracks,potholes, edge failure, slab corner broken). Henan Huineng Road And Bridge Technology Co.,Ltd. have core technology in repairing concrete road potholes,

broken corner and cracks. Achieved 1h--2h rapid open to traffic.

2.Application

1)Highways, national roads, provincial roads, airports, municipal engineering and tunnel.

2) Concrete road slab fracture, serious cracks, edge failure, potholes etc.

3) Bridge deck pavement potholes and cracks.

4)Bridge expansion joint concrete potholes and cracks.

5)Concrete road depression.

6) High-speed railways, water conservancy, wharf, parking lots and gas station.

3.Core Advantage

1)Achieved 1--2 h rapid open to traffic.

2)High compressive strength:2h>33Mpa,1d >60Mpa,meet requirement of rapid repair strength.

3)Good adhesion: Have super adhesion force with original concrete.

4)Good anti-crack property: Adapt to deformation of concrete base, and don't crack or fall off.

5)Good toughness: it is 5-8 times of normal concrete.

6)Expansion shrinkage coefficient is basically same with base course concrete.

7)Can be used in damp base course and damp environment as first-aid repair materials.

4.Construction process

5.Comparision

6.Performance Parameter

Test items | Unit | Technical requirement | Test result | Individual conclusion | |

Setting time | Initial setting | Min | ≥20 | 25 | Meet requirement |

Final setting | ≤60 | 35 | |||

Compressive strength | 2h | Mpa | ≥20 | 33.0 | Meet requirement |

1d | ≥40 | 66.1 | |||

28d | ≥50 | 90.5 | |||

Pulling strength | 28d | Mpa | ≥2.0 | 2.8 | Meet requirement |

Expansion rate | 28d | / | 0.00%-0.1% | 0.01% | Meet requirement |

7.Package and Storage

1)Package: Paper plastic composite bag packaging, 25Kg/bag.

2)Storage: Store in a cool, dry place, rainproof and moistureproof.

3)Storage period: 9 months