How to Repair Exposed Aggregate Concrete

| Min. Order: | 5 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000ton/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Concrete Repaid Repair Materials, Concrete Driveway Crack Repair Materials, Best Concrete Waterproof Repair Mortar, Best Material For Filling Cracks In Concrete Driveway, Bridge Deck Expansion Joint Repair Solution |

Product Detail

| Model No.: | BC |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | Huineng |

| Usage: | Repair Exposed Aggregate Concrete |

| Color: | Grey |

| Initial setting: | 25mins |

| Final setting: | 35mins |

| Compressive strength: | 32Mpa/2h |

| Pulling strength: | 2.8Mpa/28d |

| Expansion rate: | 0.02%/28d |

| Examining report: | MSDS |

| Certificate: | ISO9001 |

| Open to traffic: | 2 hours |

| Production Capacity: | 1000ton/month |

| Packing: | Paper plastic composite bag packaging, 25Kg/bag. |

| Delivery Date: | Within 7 working days |

Product Description

How to Repair Exposed Aggregate Concrete

Concrete pavement exponsed stones repairing process

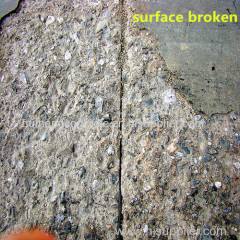

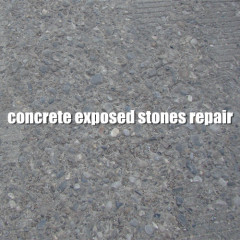

1.concrete exposed aggregate pics:

2.Why suggest you use BC concrete repair material?

Fast early strength, 2h can restore traffic

High adhesion,compression,flexural strength

Abrasive resistance is 8-10 times of normal concrete

Waterproof,anti-freeze and hydrochloric acid corrosion resistance

Beautiful,small color difference with original road surface

3.Technical data:

Test items | Unit | Technical requirement | Test result | Individual conclusion | |

Setting time | Initial setting | Min | ≥15 | 25 | Meet requirement |

Final setting | ≤60 | 35 | |||

Compressive strength | 2h | Mpa | ≥20 | 32 | Meet requirement |

1d | ≥30 | 63 | |||

28d | ≥50 | 95 | |||

Pulling strength | 28d | Mpa | ≥1.0 | 2.8 | Meet requirement |

Expansion rate | 28d | / | 0.0%-0.1% | 0.02% | Meet requirement |

4.How to use?

1) Detailed process:

Identifying→Cleaning→Washing→Wetting→Cleaning→Adding water→Mixing→Paving→Curing

2) Tools & Materials:

Tools:

High pressure blower gun

high pressure water gun(or water sprayer with water pump)

Vertical mixer

Darby

Steel trowel

Water storage barrel

Plastic film

BC type concrete repair material

Clean water

3) Repair steps:

Materials:

Step 1: Select area need to be repaired.

Step 2: Clean out crushed stone, dust by high pressure blower gun.

Step 3: Wash repair area by high pressure water gun.

Step 4: Fully wetting repair surface, until it no longer seep water.

Step 5: Clean water out from repair surface by high pressure blower gun.

Step 6: Add 17-18% water.

Step 7: Stir evenly by vertical mixer, stirring time within 5 mins.

Step 8: Pour mixed repair material to repair surface, flatten by darby promptly.

Step 9: After final setting,purling and covering by geotextile to maintain immediately.

5.Package and Storage:

1)Package: Paper plastic composite bag packaging, 25Kg/bag.

2)Storage: Store in a cool, dry place, rainproof and moistureproof.

3)Storage period: 9 months