Heating application biomass wood pellet production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5 sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Changzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Biomass Pellet Mill, Biofuel Granule Molding Equipments, Fertilizer Pellet Mil, Chipper |

Product Detail

| Model No.: | MZLH420 |

|---|---|

| Means of Transport: | Ocean, Air |

| Motor brand: | Siemens |

| Bearing: | SKF |

| Oil seal: | German |

| Main power: | 90kw |

| srew feeder power: | 2.2kw |

| Forced feeder power: | 1.5kw |

| Production Capacity: | 5 sets/month |

| Packing: | iron pallets,softe guard,accroding to customers' requirements |

| Delivery Date: | 30 days |

Product Description

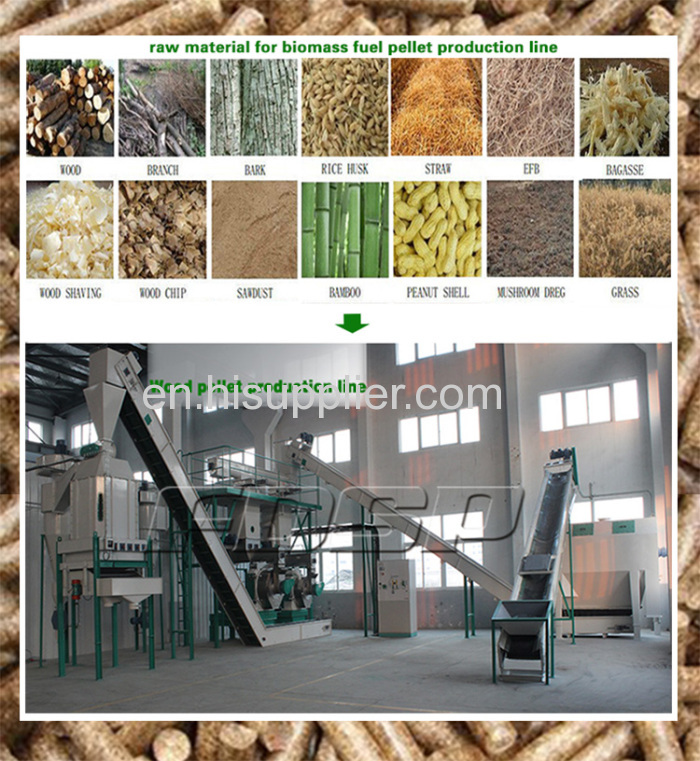

Brief introduction of complete wood pellet production line

1. This serious of complete wood pellet production line are mainly used for making the wood pellets applies for raw material like wood waste or agricultural waste, such as corn/wheat/rice straw, coffee/peanut shell, etc. The pellets are used as fuels in electricity-generating and water –heating in power plant industry, boiler factories, etc.

2. They adopt the imperative feeding device, reinforced conveyed parts, dedicated ring die, compression roller and hoop.

The main features of complete wood pellet production line

1. The main drive of our complete wood pellet production line adopts the high accuracy gear driving, so the output is 20% more than the belt drive.It makes gear directly-connecting as the driver, and is with quick-release die fixed by clamps, which can increase the output 15% more than the same type machine with belt-convey.

2. It uses the imported bearing and oil seal to make sure the high-efficiency, stable performance and low noisy of the whole machine.

3. The pelletizing chamber is equipped with air suction cooling system.

4. The feeder of our complete wood pellet production line uses variable-frequency and variable-speed motor to make sure the good quality of the pellet.

5. Advanced world standard compensatory S-shaped coupling with the structure of novel, compact, safe, low-noisy and low fault.

6. Feeder, conditioner and chute of our complete wood pellet production line made of stainless steel with long service life.

7. Our complete wood pellet production line with magnet and over load protection system, which can protect machine well during production

Product line exhibition:

Flow of biomass pellet production process:

Gold service:

We treat customers sincerely and pay more attention to how to maximize return of investment. We improve quality, reduce power consumption, shorten construction schedule, and quick feedback in terms of technology, production, engineering and service. We will furnish comprehensive, professional, and thorough service to meet customer's requirements. Thinking from customer's side, and solve problems timely.

Company view:

Certificates: