High output bio-energy wood sawdust pellet machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5 sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Changzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Biomass Pellet Mill, Biofuel Granule Molding Equipments, Fertilizer Pellet Mil, Chipper |

Product Detail

| Model No.: | MZLH4508 |

|---|---|

| Means of Transport: | Ocean, Air |

| Motor brand: | Siemens |

| Bearing: | SKF |

| Oil seal: | German |

| Main power: | 110kw |

| srew feeder power: | 3kw |

| Forced feeder power: | 1.5kw |

| Weight: | 4.4T |

| Production Capacity: | 5 sets/month |

| Packing: | iron pallets,softe guard,accroding to customers' requirements |

| Delivery Date: | 30 days |

Product Description

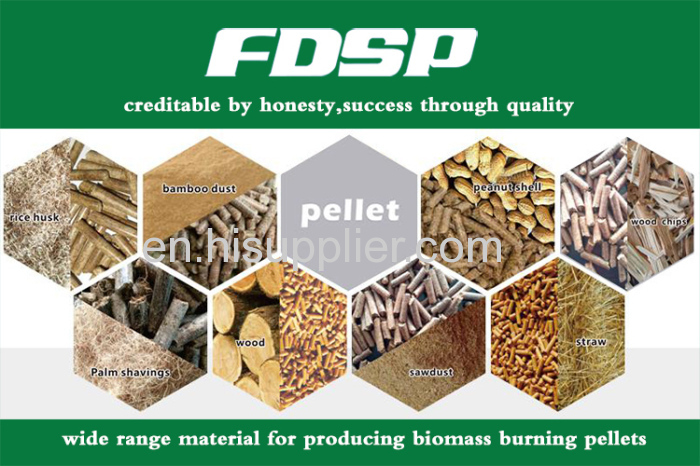

Raw material of biomass pellets:

Nearly all forestry and agro-waste material can be made into wood pellets by our ring die wood pellet mill, such as: Wood Chips, Shaving, Sawdust, Groundnut-shell, Sugarcane ,Caster Shells/Stalk, Coffee Husk, Paddy Straw, Sunflower Stalk, Cotton Stalks, Tobacco Waste, Mustard Stalk, Jute Waste, Bamboo Dust, Tea Waste, Wheat Straw, Palm husk, Soybeans Husk, Coir Pitch Barks/Straws, Rice Husks etc. The final pellets can be used for industrial boilers and large power plants as well as home heating.

Introductions of pellet making machine:

1.Biomass wood pellet machine is a kind of machine which could process sawdust,straw dust,rice husk,peanut shell,tree branches etc biomass through pre-treatment and process.Those biomass material will be solidified into high-density pellet fuel.

2.Classification:Flat die wood pellet machine,ring die wood pellet machine and vertical ring die wood pellet machine.

Advantages of wood pellet machine:

1. Biomass fuel is a kind of solid pellet fuel made up from corn straw,wheat straw,rice straw,peanut shell,rice husk,tree branches,leaves,sawdust,tree bark etc solid waste.These materials are processed with crushing,pressing and molding to small rod-like solid granular fuel.The fuel is extruded by rollers and ring die under common temperature.The density of the fuel is about 0.9-1.6g/m³.

2. The technological process:Materials collection-----Crushing-----Drying-----Molding----Packing

3. The application of biomass fuel:A new kind of bio-energy,which could talk place of wood,coal,gas etc and widely used in heating,life stoves,industrial boilers,biomass power plant etc.

Application of wood pellet machine

1.Civilian heating:high use ratio and easily storaged

2.Biomass industrial boiler:be used as the main fuel of the industrial boiler,solve the problem of environmental pollution

3.Power generation:be as the fuel of thermal power generation.

Product display:

Our features of biomass pellet machine:

Item | Wood biomass pellet machine |

Pellet Mill Type | - With Standard Feeder - With Anti-broken Feeder

|

Technical Parameters

| - Capacity: 0.8-1.2(T/H) - Size: 2800*1150*2100(mm) - Power: 75/90KW - Inner diameter of die: 420(mm) - Pellet size: 6ø, 8ø, 10ø(mm) - Net weight: 4000(kg) |

Main Features | - CE & ISO & SGS certification - Siemens motor, NSK/ SKF bearing - High precision gear-driven transmission system - One ring die and two rollers system |

Optional Parts | - Screw feeder with anti-broken - Conditioner: To adjust the moisture of raw material. - Auto cooling system for gear-box(large capacity) |

Packing Mode | Iron pallet with stretched film, etc |

MOQ | 1 set |

Payment | L/C, T/T, Western Union, Money Gram... |

Warranty | 12 months |

Main parameters of product:

Model | MZLH420 | MZLH520 | MZLH680 | MZLH780 |

Capacity(T/H) | 0.8-1.2 | 1.5-1.8 | 2-2.5 | 2.5-3.5 |

Main motor power(kw) | 75/90 | 110/132 | 160/185 | 200/220 |

Feeder power(kw) | 2.2 | 3 | 4 | 4 |

Ring die dia(mm) | 420 | 520 | 680 | 780 |

Pellets dia(mm) | 6-8 | 6-8 | 6-8 | 6-8 |

Company profile:

Packaging and delivery:

Why choose us?

Our products have passed CE certification long before, also the pellets is with SGS certification. Our company is with ISO9001 certification.

Besides, we have a professional technical team, with two departments for developing single machine and customizing complete pellet line solution. Most of our engineers are with over 20 years' experience in this field and also have a lot of experience in overseas projects.

With our outstanding technical team, we have earned a lot of certifications for our machines, together with a lot of patented design.