Kiln Tyres Manufacturers In India

| Min. Order: | 1 Ton |

|---|---|

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T |

| Supply Ability: | 3000t every year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service |

| Main Products: | Comment Plant, Vertical Roller Mill, Ball Mill, Rotary Kiln, Cement Machinery Vertical Cement Mill |

Product Detail

| Model No.: | above 1 t |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | Great wall steel casting |

| type: | Kiln Tyres Manufacturers In India |

| color: | as you like |

| material: | steel |

| weight: | 1 t |

| application: | rotary kiln or rotary dryer |

| brand: | great Wall |

| Customizable: | yes |

| Delivery date: | 25 days |

| Packing: | wooden |

| warranty: | 1 year |

| Production Capacity: | 3000t every year |

| Packing: | wooden |

| Delivery Date: | 25 days |

Product Description

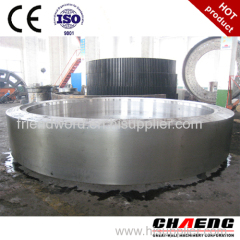

Introduction

Kiln tyre, also called rolling ring, is one important part of rotary kiln. It transmits all gravity of rotary barrel (including refractory bricks, internal devices and raw material, etc.) to supporting wheel, and ensures that barrel rotates smoothly on supporting wheel, as well as strengthen radial stiffness of barrel, therefore enough strength, durability and rigidity of rotary tyre are necessary.

Advantages

1.High strength and excellent durability.

Great Wall Casting adopts ZG45 and ZG42CrMo to manufacture the kiln tyre to guarantee its strength and toughness, so as to support rotary kiln well.

2.The advanced process of double medium quenching enhances strong adaptability

After double medium quenching, each part of the rotary tyre is forged evenly. It has characters of high stiffiness on quenching, high toughness, and good wear resistance, suitable for various bad working environments.

3. Rotary tyre has simple structure and easy to manufacture and maintain.