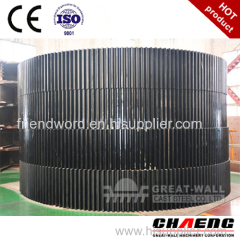

cement plant spare parts huge gears

| Min. Order: | 1 Ton |

|---|---|

| Payment Terms: | L/C, D/A, T/T |

| Supply Ability: | more than 1t |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service |

| Main Products: | Comment Plant, Vertical Roller Mill, Ball Mill, Rotary Kiln, Cement Machinery Vertical Cement Mill |

Product Detail

| Model No.: | grinding roller |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | Great Wall Steel Casting |

| color: | as you like |

| type: | vertical mill grinding roller |

| Application: | building structure |

| Certification: | ISO,CE |

| Packing: | standard export packing |

| size: | as you like |

| Process: | sand casting |

| Production Capacity: | more than 1t |

| Packing: | standard packing or nude packing |

| Delivery Date: | 25 days |

Product Description

Girth gear is key part of rotary kiln and ball mill. High quality for girth gear is required for long time operation requirement.

Advantages

1. Special Heat Treatment Technology

Great Wall Steel Casting adopts special heat treatment technology to optimize structure, improve hardness and enhance impact resistance of girth gear.

2. Long Service Life

Great Wall Steel Casting adopts high strength steel to produce girth gear. Firstly characteristics optimization of rotary kiln is done to guarantee its stability during long time operation, also to prolong its working life.

3. Factory Price Custom&Quick Delivery

Great Wall Steel Casting has strong steel casting production capability, and it can provide girth gear in large quantity with short period.

Treatment Technique

1. Shot peening

2. Bluing

3. Phosphating

4. Nickel-plated

5. Zincing

6. Heat treatment

7. Carburzing

8. Quenching

9. Tempering

10. Oiling

11. Greasing

12. Special color

13. Stain proofing

14. Pre-stretched and anti-fatigue

Testing Process

QA DOC: Chemical Composition Report, Mechanical Properties Report, UT Report, Heat Treatment Report, Dimensions Check Report

The data on chemical composition report and mechanical properties report are approved by third party, Luoyang Ship Material Research Institute, CSIC.

UT test: 100% ultrasonic test according to EN10228-3, SA388, Sep 1921 C/c etc.

Heat Treatment Report: provide original copy of heat treatment curve/time table.

.jpg)