Quality Cement Vertical Roller Mill

| Min. Order: | 1 Pack/Packs |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 50t |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service |

| Main Products: | Comment Plant, Vertical Roller Mill, Ball Mill, Rotary Kiln, Cement Machinery Vertical Cement Mill |

Product Detail

| Model No.: | 50-250 t/h |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Great Wall |

| Production Capacity: | 50t |

| Packing: | packing by wood |

| Delivery Date: | 1 mouth |

Product Description

| Application | Cement Plant, Clinker Grinding Unit, Thermal Power Plant |

| Capacity | 50-250 t/h |

| Motor Power | 1000-5000kw |

| Fineness | 3300-3800 cm²/g |

Introduction of

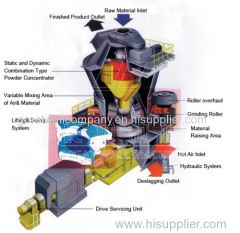

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc.

Vertical Roller Mill has a Low Investment Cost

VRM(Vertical Roller Mill) system can crush, dry, grinding, classifying, so the system is simple, and occupation area is about 50% of ball mill system. In addition, it can be the outdoor installation that reduce a large number of investment costs.

Vertical roller mill has a Low Operation Cost

High efficiency: roller compacted materials directly onto the grinding disc, so power consumption is low. Compared with ball mill, it saves energy consumption by 30% ~ 40%.

Less wear and tear: As the roller is not in direct contact with the disc, and material of the roller and liner is high quality, so life time is long.

High Drying Ability

As the hot air inside contacts directly with the material, drying ability is higher, and it saves energy. By regulating the air temperature, it can meet requirements with different humidity.

Stability of Product Quality

As the material stays in the VRM for a short time, it is easy to detect and control the product particle size and chemical composition, to reduce duplication of milling, stable product quality.

Maintenance Convenience

By repairing fuel tank, rotating the arm, it is fast to replace the roller sleeve, and liner, and reduce the downtime loss.

you can get more:http://www.great-wall.co