2 layers door-JXF wall mount distribution box/enclosure with one step one time molding technology

| Min. Order: | 100 PCS |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10000PCS/PER MONTH |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

| Main Products: | Distribution Box, Low Voltage Switchgear Cabinet |

Product Detail

| Model No.: | JXF-1 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | CHKX |

| Material: | Metal |

| Color: | RAL7032/RAL7035/Customized |

| Size: | Standard or customized |

| Protection level: | IP65 |

| Process technology: | CNC punch, laser cutting |

| Surface treatment: | Zincing, chroming, powder coating |

| Acessories: | hinges,lock,standard screw,mounting panel |

| Package: | Carton or customization |

| Transpoart: | By sea or by air |

| Production Capacity: | 10000PCS/PER MONTH |

| Packing: | Carton or customized |

| Delivery Date: | 30 days |

Product Description

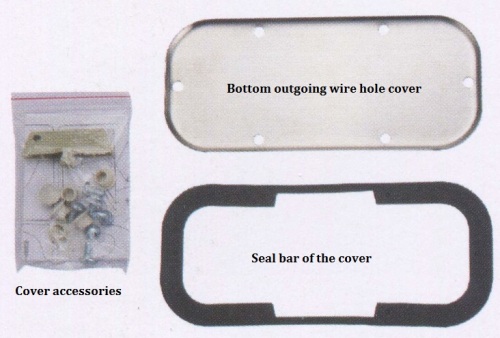

JXF power distribution box enclosure It's entirely made of cold-rolled steel plate, adopt advanced producing technology and automatic NC(numerical control) producing line which is the only and leading level in China to finish with one step processing technology. Box surface is beautiful and durable, with electrostatic spraying of epoxy polyester powder. Seal bar is finished by advanced importing pouring machine with one step molding technology, have dustproof, rain-waterproof etc merits, box bottom has outgoing wire hole which has cover(cover with seal bar), protection degree can reach IP65. Inside box has mounting plate which can install any electric apparatus, box door can be opened more than 90 degree, rotate flexibly.

JXF power distribution box enclosure

It's entirely made of 1.2mm cold-rolled steel plate, adopt advanced producing technology and automatic NC(numerical control) producing line which is the only and leading level in China to finish with one step molding technology. Box surface is beautiful and durable, with electrostatic spraying of epoxy polyester powder.

Seal bar is finished by advanced importing pouring machine with one step molding technology, have dustproof, rain-waterproof etc merits, box bottom has outgoing wire hole which has cover(cover with seal bar), protection degree can reach IP65. Inside box has mounting plate which can install any electric apparatus, box door can be opened more than 90 degree, rotate flexibly.

1.Seal bar finished by advanced importing pouring machine with one step molding technology Advantages: Compared with other traditional stickup seal bar, this seal bar with one step molding technology have below merits: waterproof, rainproof, high temperature resistance, high strength, beautiful appearance etc. 2. Hinge(Dischargeable hinge, connect with locking nut) Advantages: Box door can still open successfully even it was be squeezed, can swap left to right, compared with traditional welding hinge, have below merits: more beautiful, high strength, won't dis-welding, won't broken etc. 3.Box body--processing in automatic NC(numerical control) producing line Advantages: Special edge rolling process, improved anti-press strength, and omit welding process, improved producing efficiency greatly(Producing capacity is 20 times of the traditional producing way), daily output 1500sets. Product components list: Surface Finish -Mounting plate: zinc coated Protection: Protection degree:IP65 Impact resistaance:IK10 Usage:

|