20000kVA furnace transformer SABS SANS Standard

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6000PCS |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Wind Power Generation Combined Substation, American Type Pad Mounted Substation, High Impedance Furnace Transformer, 50MVA 115KV Power Transformer |

Product Detail

| Model No.: | 20000kVA/230kV |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | sinopower |

| ANSI Standard: | furnace transformer |

| Electric Arc Furnace: | EAF transformer |

| IEC Standard: | 220kV JB/T 9640-1999 |

| EN Standard: | steelworks |

| SABS Standard: | 30kV |

| Nynas transformer OIL: | Kema Certification |

| SABS SANS: | 220kV |

| Production Capacity: | 6000PCS |

| Packing: | Naked Packing |

| Delivery Date: | 6 months |

Product Description

ARC Furnace Transformer Technical Description

Based upon world-wide advanced technology and also incorporates the experiences of internationally leading transformer companies (such as ABB, Siemens, Alstom) as well as our own long-term experience. Through innovation and optimization, low loss, low noise, low partial discharge and high short circuit withstand capability are achieved in our Power Transformer and Furnace Transformer series. The carefully made Sinopower Furnace Transformer series, being energy saving and environmentally friendly, shall conform entirely with up-to-date specified standards according to customer's specification, and are proud of the following outstanding features:

1. Low Loss and Low Noise

The core laminations are composed of imported high quality grain-oriented cold-rolled silicon steel sheets with chamfered joints and the joints are step-lapped with 5 steps, thus ensuring low loss and low noise. The inside of the tank is lined with magnetic and /or copper shields. Measures have been taken for metallic structural parts located in high magnetic field, to reduce stray loss and thereby the total load loss, and to relieve local overhearing. Correct arrangement for the leading wire of LV side, to reduce the stray loss.

After stacking, the core are pressed integrally and finally glued together by epoxy resin on the cut edges, so that the three limbs and the upper and lower yokes are bonded together into a rigid, vertically straightened entity, together with the plate-type upper and lower frame. That can reduce the noise effectively against vibration from core.

2. Low Temperature Rise

Using the low-magnetic steel plates reduce magnetic flux leakage cased by the high current. Put the block plate of the oil path according to the hot spot temperature rise which calculated by the advanced software. Using guide oil flow structure inside of the tank to reduce the average temperature rise. According to the different internal temperature using different insulation class material guarantee transformer hot life. The whole tank cover and LV tank wall is made by non-magnetic steel plate, to reduce the temperature rise caused by the structure hardware.

3. Stable Structure, Strong Ability of Short Circuit

HV Winding uses the half hard self-adhesive transposition wire. Using the separate voltage regulation coil, arrange the oil path according to the strict requirement of the Ampere-Turns balance, reduce the axial electric power. There're sticks outside of every coil, to prevent shift position caused by the short circuit, enhance the dynamic stability of the winding. LV Winding uses continuous double coil winding, enhance the strong ability. Top press board and layer supporting board use high density pressed wooden plate. Using the spring pressure screw to increase pre-tightening force, guarantee the reliable structure and strong ability of short circuit.

4. Safe and Reliable Service

Reliability is the everlasting objective of SINOPOWER. Partial discharge of finished products are constantly kept below 50pC, ensuring that the transformers can be operated under long service voltage and occasional over-voltage without trouble. Low current density in winding conductor and appropriate cooling arrangement ensure that the winding temperature rise and top oil temperature rise are lower than that specified standards and that the mechanical stress in winding conductor during short circuit does not exceed certain safe limit. Together with technological procedures during manufacture and other means to elevate mechanical strength, SINOPOWER transformers can withstand severe short circuit in all cases during service.

5. Easy Erection and Maintenance

To minimize erection work at jobsite, SINOPOWER transformers are so fabricated that lifting the active part out of the tank for inspection after arrival at site is not mandatory. Besides, all components to be mounted on the transformer at site have been pre-assembled before dispatch, and all secondary rings have been laid down into conduits on the transformer and connected to the terminals in the control cabinet or terminal box. Little maintenance work is required for the cooling devices.

6. Careful Fabrication

Vertical winding machines with tension device are used for HV winding, so that the windings can be wound more tightly and therefore mechanically strength as a whole. All insulation parts subjected to mechanical stress during short circuit, such as spacers in windings are made with T4 densified pressboard to reduce shrinkage. Drying process for the windings are carried out twice, once for the individual windings, and again for the assembled phase block. After core and coil assembly, an additional vapor phase drying (VPD) is once more carried out to ensure that all insulation parts are thoroughly dried and no further shrinkage is possible to occur during service.

All the high voltage terminals and nearby metallic structural parts are rounded up to prevent partial discharge. High voltage bushing terminals are contained within turrets, and kept concentric with the turret. All the leads are properly crimped and metallized to be rounded up. VPD process insures that the moisture content within the transformer is kept at a very low level, and the core and coil assembly is once more cleaned by condensed vapor flowing down the surfaces.

The fabricated tanks are relieved from welding stress and shot-blasted integrally, so as to be free from oil leakage trouble and to give the tank a clean, pleasant looking appearance. High quality paint is applied as surface finish of the tank and exposed steel parts.

7. Clean Work Environment

The winding manufacture, winding assembly and core and winding assembly work are all proceeded in totally closed clean shops. The cleanliness and temperature stability requirement of the area are the same as that required for the manufacture of 500kV class transformers. Even metallic particles on the crane's tracks are cleaned up by magnet.

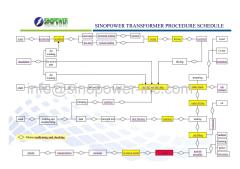

8. Quality Assurance

Quality assurance rules are observed from the very being of acquisition of raw materials and components. No rusting, colliding, scratching or hammering are allowed for steel plate. Special attention is paid to those parts susceptible to oil leakage. All the gasket groove surfaces are carefully machined, and limits are provided to prevent the gasket material from being compressed over its elastic limit. The transformer tank is integrally shot-blasted, and burrs and welding slags are thoroughly removed. Radiators and other component parts are tested in accordance with their respective service condition. Usually the upper and lower parts of the tank are bolted together with double gasket grooves in their jointing surface and kept tight with high quality gasket material, effectively preventing oil leakage from the jointing surface. If required by the customer, the upper and lower part of the tank can also be welded oil tight.

Quality assurance rules are also observed for all insulating parts, from raw material to final assembly. Strict regulations are observed for drying, wrapping and storage, preventing the absorption of moisture, swelling, and deformation. Finished spacers and pressure rings are all stored in practically isothermal oven. Finished windings, after pressing and adjustment are conserved in specially made isothermal cylinders. For the core and coil assembly, the time interval between lifting out from oven and tanking is strictly controlled, so that no significant absorption of moisture can occur due to exposure.

9. Main components

9.1 Because of good relationship and long-term co-corporation with all well-known sub-suppliers, SINOPOWER can meet the requirements of customers with whatever types of components they wish to have.

9.2 Our own patented low noise fan is an assurance that forced-air cooled transformers can be made with noise level even lower than 62 dB.

9.3 Flat plate type radiators, developed and produced by SINOPOWER itself are highly efficient, better quality and best delivery time, and are also being supplied to other transformer manufactures in world.