Pneumatics Pulse Valve Stainless Steel Dust Collecting Valve G1 1/2" G3/4"

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

| Main Products: | ABS Solenoid Coil For Automotive Solenoid Valve Plug-type KVN013, 4V210 Solenoid Coil For 4V Magnetic Valve Serie, HC-16 Coil For Hydraulic Electromagnetic Valves, Proportional Valve Solenoid Valve, Q23XD-2 Solenoid Coil For Water Valve Serie KVN073 |

Product Detail

| Model No.: | XQX-II-80S |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Power: | Pneumatic |

| Standard or Nonstandard: | Standard |

| Pressure: | Low Pressure |

| Material: | Brass |

| Temperature of Media: | Low Temperature |

| Media: | Gas |

| Brand Name: | KVN |

| Certification:: | Iso9001:2000 , CE |

| Manfacturer:: | Yes |

| Valve:: | Solenoid valves |

| Power Supply:: | AC Solenoid Valve |

| Payment Term:: | L/C , T/T , Paypal |

| Working Pressure: 0.3-0.6MPa: | 0.3-0.6MPa |

| Ambient Temperature: -15---60celsius: | -15---60celsius |

| Designing Pressure: 0..035-0.8MPa: | 0..035-0.8MPa |

| Diaphragm Material:: | Nitrile |

| Type:: | Pilot Operated |

| Production Capacity: | 3000 |

| Packing: | box and carton |

| Delivery Date: | According to purchasing quantity |

Product Description

Model NO.:

Good quality membranes shall be selected and used for all the valves, with each part checked in each manufacturing procedure, and put into the assembly line conforming to all the procedures. Every finished valve shall be taken the electriferous blowing test.

| NO. | Type | Qty.(diaphragm) | Input Size | Ouput Size |

| 1 | XQAL-P-76 | 1 | G3" | G3" |

| 2 | XQAL-P-102 | 1 | G4" | G4" |

| 3 | XQT-Y-75S | 2 | G3" | G3" |

| 4 | XQT-Y-76S | 2 | G3" | G3" |

| 5 | XQT-Z-55S | 2 | G2" | G2" |

| 6 | XQTH-Y-75S | 2 | G3" | G3" |

| 7 | XQAU-Y-75S | 2 | G3" | G3" |

| 8 | XQW-Y-76S | 2 | G3" | G3" |

| 9 | XQJ-Y-76S | 2 | G3" | G3" |

| 10 | XQNG-Y-76S | 2 | G3" | G3" |

| 11 | XQX-II-80S | 2 | G3" | G3" |

| 12 | XQCD-80S | 2 | G3" | G3" |

| 13 | XQS-Z-25 | 1 | G1" | G1" |

| 14 | XQS-Z-20 | 1 | G3/4" | G3/4" |

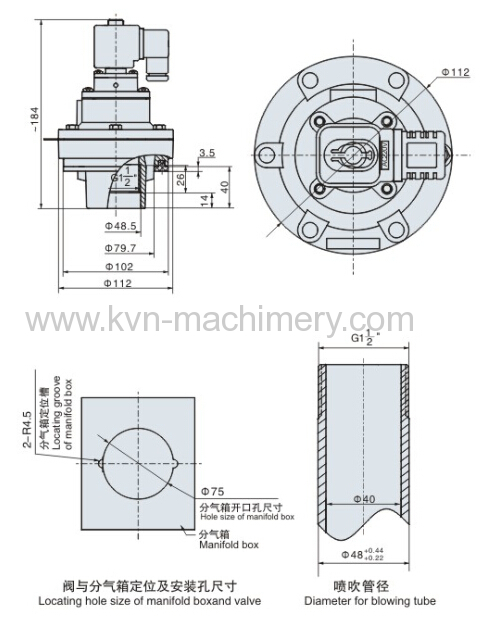

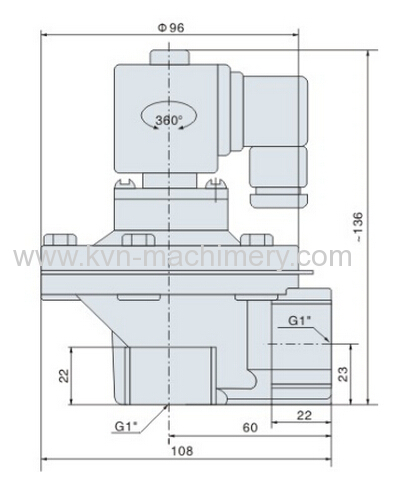

Overall Dimension:

Usage:

Electro-magnetic valve (also called diaphragm valve) is the "switch" for compressed air in the dust clean blowing system of the pulse bag filter. Controlled by the output signals of the pulse jet control device, it makes dust clean to the filter bags cell by cell to keep the resistance of the baghouse within the set range and thus guarantee the processing functions and the dust-collecting efficiency of the baghouse.

Y type electro-magnetic pulse valves are embedded valves (also called submerged ones) which are directly installed on the manifold box. They have better flow characteristics and operate with reduced pressure loss, therefore, they are suitable for conditions where the pressure of the gas source is relatively low.

Z type electro-magnetic pulse valves is a right-angle valve, with the 90 degree angle between the inlet and outlet, which is suitable for the installation connection between the gas dome and the baghouse blow tube to provide good air flow and dust clean pulses satisfying the requirements.

DD type(with 2nuts) electro-magnetic pulse valves are the right-angle valve same as Z type which is suitable for the installation connection between the gas dome and the baghouse blow tube. There are fixed nut at both ends which make it easy to install and use the valve.

ZT type electro-magnetic pulse valves are the straight valve inline, with the 180degree angle between the inlet and outlet, which is suitable for the installation connection between the inlet and gas dome, outlet and the blow tube to provide good air flow and dust clean pulses satisfying the requirements.

Working Principle:

The electro-magnetic pulse diaphragm valve is composed of two gas cells. When the compressed air is connected, it comes into the back gas cell through the orifice. The pressure in the back gas cell pushes the diaphragm closely against the outlet of the valve and the electro-magnetic valve stays in the "closed" condition. The electrical signals from the pulse jet control device move the armature of the electro-magnetic pulse valve. The air escape of the back gas cell opens and the back gas cell loses pressure quickly, thus the diaphragm moves back and the compressed air blows through the valve outlet. The electro-magnetic pulse valve comes into the "open" condition. When the electrical signals from the pulse jet control device disappear, the armature of the electro-magnetic pulse valve returns to its original position. The air escape of the back gas cell closes and the pressure in the back gas cell rises, which pushes the diaphragm closely against the valve outlet. The electro-magnetic valve comes into its "closed" condition again.