LDPE mat extrusion machine/production line(1200mm)

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100 sets/year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

| Main Products: | Plastic Pipe Machine, Plastic Board Machine, Wpc Sheet Machine, Pvc Foam Board Machine, Plastic Profile Machine |

Product Detail

| Model No.: | 65/33 |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | Ents |

| Power: | 160kw |

| Production Capacity: | 100 sets/year |

| Packing: | wooden |

| Delivery Date: | 45 workdays |

Product Description

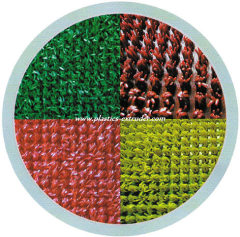

LDPE mat extrusion machine/production line(1200mm) is a new extrusion line of our company,this machine line could produce a new kind plastic grass mat with different colors.

And all the materials could be recyling LDPE!!

LDPE grass mat production line Introduction:

Electric Power Equipment

Voltage:380V,50HZ

Phrase:3 Phrases 4 wires

Total power:160kw

Dimension of line:15mX4mX2.5m

Effective width of grass mat=1200mm

Grass height=11-20mm

The Mat Production Line Equipment List

1, Single screw extruder : FSJ-65X33 1 set

Single screw extruder: FSL-90X33 1 set

(including automatic feeding system)

2, Two-layer flat mold 1 set

3, Forming system 1 set

4, Lengthwise cutting system 1 set

5, 1st Haul-off unit 1 set

6, Grass-lifting unit 1 set

7. Grass-shaping unit 1 set

8. 2nd haul-off unit 1 set

9. Grass-lifting unit 1 set

10. Length-counting cutter 1 set

11. Winding machine 1 set

12, Electric control system 1 set

Technology and Service:

1. Seller supply full set of technical document, cutter and other full document (write in English).

2. Seller supply training for buyer's staff until buyer can produce the eligible production independently.

3. Seller is responsible for installing, testing, adjusting and debugging the machines in buyer's factory.

4. Buyer should pay the expense for our engineers including for our engineer including round-

way tickets, inland traffic, lodging and boarding fee when the machine is installed, tested and maintained.

5. Seller will go to install machines after the machine is arrived at buyer and buyer will have prepared all

conditions (including power, water, compress air, tools and materials for producing pipe, etc) for installing

and testing these machines. Buyer should pay 60USD/day.

6. When installing,people of both sides cooperate well and carefully,buyer supplies convenient working

condition,any problem, should discuss peacefully and kindly.

7. Buyer supply proper working tools, equipments and other conditions.

8. The expense including the accommodation and materials of the trial-

run the machine for testing and other expenses(electric, water, air and worker) will be on seller's account,

if the buyer or their representatives do the inspection of the machines before shipment.

9. Guarantee period: 14 months after shipment (the date of B/L)

http://www.plastics-extruder.com