Sunflower seed oil refining equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | according to capacity |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Cottonseed Protein Plant, Oil Refining Equipmet, Oil Extraction Equipment, Whole Set Of Oil Equipment |

Product Detail

| Model No.: | according to capacity |

|---|---|

| Means of Transport: | Ocean, Land |

| Production Capacity: | according to capacity |

| Packing: | according to requirement |

| Delivery Date: | within 45 days |

Product Description

Sunflower seed oil refining equipment

1.Why should be refined the crude Sunflower seed oil

The crude oil obtained either from expellers or solvent extraction plant contains impurities, which must be removed to make the oil edible, more palatable and stable against rancidity upon storage. The process of removing these impurities is called refining.

2.Sunflower seed oil refining plant method:

1)chemical refining 2) physical refining 3)chemical-physical refining

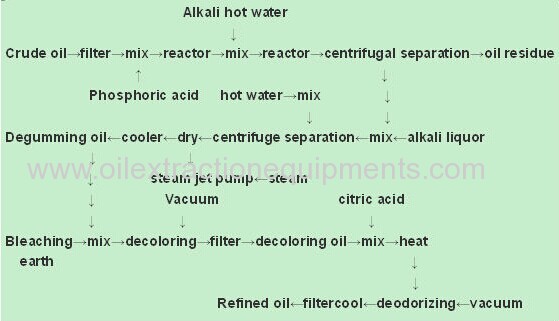

3,Process of the sunflower seed oil refining

1.Degumming with water to remove the easily hydratable phospholipids and metals.

2.Addition of a small amount of phosphoric or citric acid to convert the remaining non-hydralable phospholipids (Ca, Mg salts) into hydratable phospholipids.

3.Neutralising of the free fatty acids with a slight excess of sodium hydroxide solution, followed by the washing out of soaps and hydrated phospholipids.

4.Bleaching with natural or acid-activated clay minerals to adsorb colouring components and to decompose hydroperoxides.

5.Deodorising to remove volatile components, mainly aldehydes and ketones, with low threshold values for detection by taste or smell. Deodorisation is essentially a steam distillation process carried out at low pressures (2-6 mbar) and elevated temperatures (180-220°C).

4,Our machines