coconut charcoal packing big bag

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2000T/Year |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | FIBC Big Bag Jumbo Bag, Heavy Duty Woven Polypropylene Fabric Tote, PP Woven Flexible Intermediate Bulk Container, Iron Ore Transport Packaging Container, Custom Made Giant Sack For Australian Buyer |

Product Detail

| Model No.: | U-panel |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Transport |

| Type: | Fibc bag |

| Material: | PP |

| Brand Name: | Ebang |

| Top: | open |

| Bottom: | Plain |

| Loop: | Side-Seam Loop |

| SF: | 5:1 |

| SWL: | 500~1500KG |

| Size: | Customized |

| Raw Material: | 100% new PP |

| Production Capacity: | 2000T/Year |

| Packing: | Soft Packaging |

| Delivery Date: | 25 Days |

Product Description

Why choose super sack/ big bag/FIBCs/bulk bags

1.FIBCs have the lowest package to product weight ratio of any intermediate industrial container. Ship one metric ton of product with a package weight as little as 5-7 lbs (2-3 Kg)

2.Can be handled, transported and stored without pallets due to integrated lifting loops

3.When empty they are lightweight and can fold flat to take up a fraction of the space required for other industrial packages

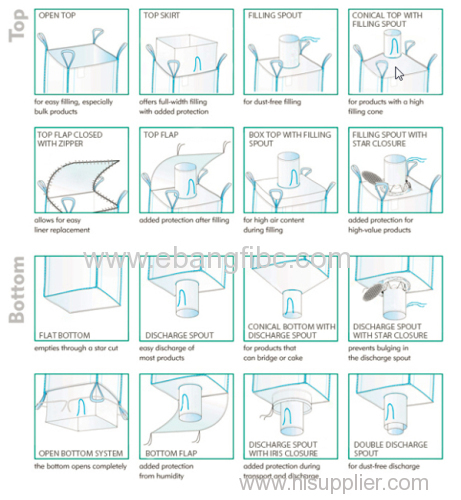

4.Can be customized to meet your needs (Size & Capacity,Filling & Discharging Features, Barrier Properties, Handling Features, etc.)

5.Recyclable

Formstable 4-Loop FIBCs with Baffle

One way that form-stability can be achieved is by sewing polypropylene "baffles" to sides of the FIBC,

across each of the four corners.

When the FIBC is filled, the baffles prevent the sides from bulging out – a stable shape is achieved.

ebang two types of baffles:

Ebang's Standard Baffle | Ebang's Net Baffle |

A standard baffle is a polypropylene panel with properly-spaced holes to allow the free flow of product during the fill and discharge process | The innovative Greif Net Baffle is constructed with polypropylene tapes and strings. This innovated design possesses minimal surface area, which ensures full and even distribution of your product and effective flow during filling and discharging. |

Corner Loops

Flat fabric (U-panel or 4-panel) baffle bag

Lifting loops sewn to the vertical seams

Safe Working Load | Safety Factor | Design |

300-2000 kg | 5:1 | Single Trip |

300-1500 kg | 6:1 | Multi Trip |

300-1500 kg | 6:1 | UN Dangerous Goods |

Cross Corner Loops

Circular or flat fabric

Lifting loops sewn cross corner

Safe Working Load | Safety Factor | Design |

300-1500 kg | 5:1 | Single Trip |

300-1500 kg | 6:1 | Multi Trip |

300-1500 kg | 6:1 | UN Dangerous Goods |

Tunnel Loops

Flat Fabric

Lifting loops formed out of fabric

Safe Working Load | Safety Factor | Design |

300-2000 kg | 5:1 | Single Trip |

300-1500 kg | 6:1 | Multi Trip |

(the specification and size can be customized)

(1) Characteristics: Our products with different function like dust-proof, moisture-proof, radiation-resistant, safety, fastness,etc.

(2) It has high strength structure, easy to load and unload.

(3) Can widely used for packing lead zinc ore, copper ore, sandstone, cement, chemical products, grain, ore product and various kinds of powder and granular goods.

(4) Load: 0.5-3T; capacity: 500-2300L

About Ebang

Anhui YiBang New Material Technology Co., Ltd is a professional manufacturer of FIBC (Big Bag/Jumbo Bag).

We produce an extensive line of Flexible Intermediate Bulk Containers (FIBCs) to meet both large and small volume requirements.

Our products can be used for a wide range of solid and ponder products (Chemical, Mineral, Food, Agricultural, etc.)

Our adventages:

1.More than 10 years experience for manufacturing FIBC/ Big Bag

2.We are the direct factory, best price offer

3. We can provide OEM services for buyers

4. Stable productivity,the shortest delivery time

5.Flexible payment terms for old customers.

6.24hours services before and after sales,

make you know clear about the production situation of your order and your container route after shipment.

Manufacture Process

Raw material

We use only 100% virgin PP to make sure that our good quality.

I can guarantee that you won't find a single grain of second hand PP in our raw material.

Tape Stretching

From the very basic raw material 100% virgin PP,

we make the PP tape through extruding machine and drawing machine.

The know-how of the mixture of raw material and our experienced skill in drawing process,

we can manufacture the tread with specified strength. And with the special treatment of the raw material ,

we can add UV or rediation protection function

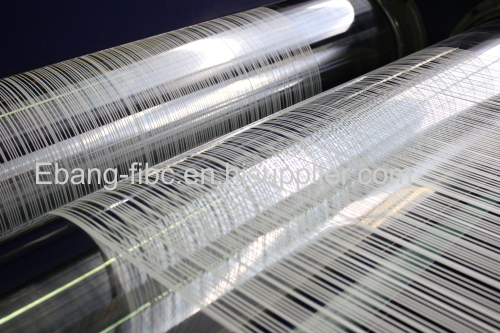

Weaving

And skilled workers weave the tape into plastic coth with Circular looms

Cutting

We are also able to print logos or any draft you provide on the surface of the plastic fabrcs,

then cut the plastic cloth into the specified size.

Sewing

The stitchers then sew the fabrics into one bag.