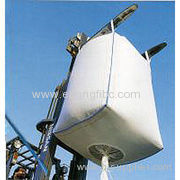

Good quality big bag

| Min. Order: | 2000 Piece/Pieces |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2000T/Year |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | FIBC Big Bag Jumbo Bag, Heavy Duty Woven Polypropylene Fabric Tote, PP Woven Flexible Intermediate Bulk Container, Iron Ore Transport Packaging Container, Custom Made Giant Sack For Australian Buyer |

Product Detail

| Model No.: | U-panel |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Chemical |

| Type: | Woven Bag |

| Material: | PP |

| Brand Name: | Ebang |

| Specification: | 91.5x91.5x101.5cm |

| Certificate: | ISO9001:2000 |

| Export Area: | USA |

| Lifting Loop: | 2 loops |

| SWL: | 500kg |

| Color: | Yellow |

| Top: | Open |

| Bottom: | Plain |

| Production Capacity: | 2000T/Year |

| Packing: | Soft Packaging |

| Delivery Date: | 25 Days |

Product Description

About the product

FIBCs are most often made of thick woven polyethylene or polypropylene, either coated or uncoated, and normally measure around 110 cm or 45-48 inches in diameter and varies in height from 100 cm up to 200 cm or 35 to 80 inches. Its capacity is normally around 1000 kg or 2000 lbs, but the larger units can store even more. A bulk bag designed to transport one metric ton of material, will itself only weigh 5-7 lbs.

Transporting and loading is done on either pallets or by lifting it from the loops. Bags are made with either one, two or four lifting loops. The single loop bag is suitable for one man operation as there is no need for a second man to put the loops on the loader hook. Emptying is made easy by a special opening in the bottom such as a discharge spout, of which there are several options, or by simply cutting it open.

We have been producing the 100% Virgin PP Big Bags for several years. We are the OEM factory for a large America retailer for many years, so the quality of this type of bag is very stable.

Specification

Weight | 0.93 kg |

Loop | 0.43m x2, 50g/m |

Size | 91.5x61x61 |

Loading Weight | 500kg |

Top | Open |

Bottom | Plain |

Color | White with Printing Logo |

Or we can manufacgture the bags according to your specification.

About us

Anhui YiBang New Material Technology Co., Ltd, as an industry and trade integration, is specialized in producing various FIBC (big bag/jumbo bag/container bag/super sack/ton bag). Owning the whole chain from design, R&D to processing, we have introduced the most advanced equipment for drawing, circular weaving, laminating and also have dust-free workshop. The strength of our products is now increased by 20% than common ones.

Located in the fantastic city of Maanshan, the factory covers a large area of 10000 square meters factory and 3000 square meters warehouse. The regular inventory can reach 10000pcs due to a monthly output up to 150000pcs. . the company has certificates of ISO9001:2008, ISO14001 Environment System Certification, UN International Certification, American AIB Certification, and OHSAS18000 Occupational Health and Safety Management System Certification.

We offer normal container bags, while specialized in a wide range of bags with function such as anti-UV, anti-radiation, anti-static, conductive, heat-resistance, etc.

Anhui YiBang New Material Technology Co., Ltd, as a branch and the only professional sales office of Di Yi, has years' of experience in exporting overseas. As always. We are ready to offer you the whole service from design, selling, shipping and after-sales perfectly.

The company always adhere to the principle "best quality, best service". Choose us, choose BEST.

Basic Information

1.More than 10 years experience for manufacturing FIBC/ Big Bag

2.Total Number of Employee: 155

3.Number of R & D Staff: 12

4.Factory Area: 10,000 m2

5.Warehouse: 3000m2

6.Whole factory is controlled by ERP-Enterprise Resource Plan

We are provide below ranges of products/service:

1.FIBC/ Big Bag

2.Dry Bulk Liner

3.Flexitank

4.Packaging Optimize Solution

5. Grocery Bag/ Shopping Bag

6.OEM Service

Manufacture Process

Raw material

We use only 100% virgin PP to make sure that our good quality. I can guarantee that you won't find a single grain of second hand PP in our raw material.

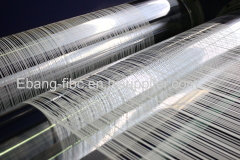

Tape Stretching

From the very basic raw material 100% virgin PP, we make the PP tape through extruding machine and drawing machine. The know-how of the mixture of raw material and our experienced skill in drawing process, we can manufacture the tread with specified strength. And with the special treatment of the raw material , we can add UV or rediation protection function.

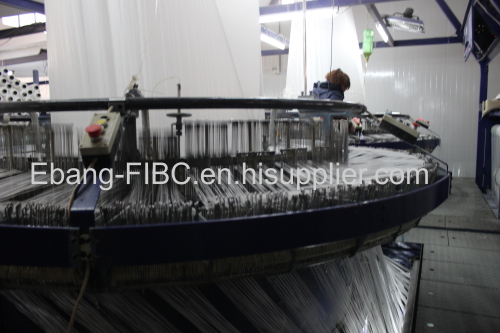

Weaving

And skilled workers weave the tape into plastic coth with Circular looms

Cutting

We are also able to print logos or any draft you provide on the surface of the plastic fabrcs, then cut the plastic cloth into the specified size.

Sewing

The stitchers then sew the fabrics into one bag.

We can customize various kinds of type and size, such as the following:

90 x90x100cm | 90 x90x160cm | 90 x90x140cm | 90 x90x180cm |

90 x90x120cm | 100 x100x100cm | 100 x100x120cm | 100 x100x140cm |

100 x100x160cm | 100 x100x180cm | 95 x95x140cm | 105 x105x210cm |

DIA110x90cm | DIA110X110cm | 105 x105x135cm | 105 x105x240cm |

Our Advantages

1.We are the direct factory, best price offer

2. High quality control, Certificate:ISO9001-2008

3. We can provide OEM services for buyers

4. Stable productivity,the shortest delivery time

5. professional technical team

6.Flexible payment terms for old customers.

7.24hours services before and after sales,

make you know clear about the production situation of your order and your container route after shipment.

Packaging & Delivery

Packaging Detail: | 10bag/package or 20bag/package Regular size: 3000px*750px*500px Bearing capacity: 200packages/20'container ,350packages/40'container |

Delivery Detail: | 15days~25days |