Anti static open top FIBC

| Min. Order: | 2000 Piece/Pieces |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2000T/Year |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | FIBC Big Bag Jumbo Bag, Heavy Duty Woven Polypropylene Fabric Tote, PP Woven Flexible Intermediate Bulk Container, Iron Ore Transport Packaging Container, Custom Made Giant Sack For Australian Buyer |

Product Detail

| Model No.: | U-panel |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Ebang |

| Specification: | 91.5x61x61cm |

| Certificate: | ISO9001:2000 |

| Export Area: | USA |

| Lifting Loop: | 4 loops |

| SWL: | 1000kg |

| Color: | White |

| Top: | Open |

| Bottom: | Plain |

| Production Capacity: | 2000T/Year |

| Packing: | Soft Packaging |

| Delivery Date: | 25 Days |

Product Description

FIBC CLASSIFICATION TYPE A, B, C, D

FIBC are classified according to one of four types: Type A, Type B, Type C and Type D. The types are defined by the construction of the bulk bag, the nature of their intended operation and associated performance requirements. The table below identifies which type of FIBC is appropriate depending on the sensitivity to ignition of the product being packaged, and of the surrounding atmosphere. The sensitivity to ignition of the product being packaged, i.e. the bulk product, is defined by its minimum ignition energy, MIE. Surroundings are classified in increasing sensitivity to ignition by electrostatic discharges as non-flammable, explosive dust atmosphere, or explosive gas or vapour.

Type D FIBC are also called antistatic bulks bags They are made from static protective fabric designed to safely prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges, without the need for a connection from the bulk bag to ground or earth.

1. Quick Details

--Top Option (Filling): Top Fill Spout

--Loop Option (Lifting): Cross Corner Loop

--Bottom Option (Discharge): Flat Bottom

--Safety Factor: 5:1

--Feature: Breathable

--Loading Weight: 1 ton

--Place of Origin: Anhui, China (Mainland)

--Brand Name: Ebang

--Scientific name: Jumbo Bag

--Material: 100% new pp

--Color: white, yellow, blue

--Weave construction: 13*14

--Usage: Mineral/cement/sand/chemical

--Linner: available

--UV treatment: available

--Printing: available

--Lamination: available

2. Product Specification

Description | FIBC |

Raw Material | 100% virgin PP |

Color | All kinds of colors |

Printing | One side or both sides in multi-colors with film or non film |

Width | From 300-700mm |

Length | As the customer's requirement |

Weave | 10×10, 11×11, 12×12, 14×14, 12×11 or be customized |

Denier | 600D to 1500D |

Weight/ m² | 60g-270g |

Surface dealing | Anti-slip or plain |

Top | Full open/with spout/with skirt cover |

Bottom | Flat/plain/with spout |

liner | Coated or with liner bag for moisture proof |

Sewing | Plain/chain/chain lock with optional soft-proof |

Lifting loop | 2 or 4 belts, cross corner loop/fully loop/loop in loop |

Ropes | 1 or 2 around the bag body |

SWL | 500kg-3000kg |

Safty Factor | 3:1, 5:1, 6:1 |

Payment Term | T/T(30% of amount deposit and 70% balabce after receiving the B/L copy) |

Delivery Time | 25 days |

3. Product Range:

We can customize various kinds of type and size, such as the following:

90 x90x100cm | 90 x90x160cm | 90 x90x140cm | 90 x90x180cm |

90 x90x120cm | 100 x100x100cm | 100 x100x120cm | 100 x100x140cm |

100 x100x160cm | 100 x100x180cm | 95 x95x140cm | 105 x105x210cm |

DIA110x90CM | DIA110X110CM | 105 x105x135cm | 105 x105x240cm |

About us

Basic Information

1) ISO9001:2000, ISO 9001:2008, Quality License of exporting dangerous packaging container (big bag/jumbo bag)

2) Reorganized in 2014 one of the most advanced company in plastic bag industry in China. (FIBC big bag, container bag)

3) Set up branches in Ningbo, Hefei, and so on. (pp container bag, fibc big jumbo b

4) Manufactured the Jumbo bag for the nuclear waste in Fukushima nuclear power plant in 2011.

We are provide below ranges of products/service:

1.FIBC/ Big Bag

2.Dry Bulk Liner

3.Flexitank

4.Packaging Optimize Solution

5. Grocery Bag/ Shopping Bag

6.OEM Service

Manufacture Process

Raw material

We use only 100% virgin PP to make sure that our good quality. I can guarantee that you won't find a single grain of second hand PP in our raw material.

Tape Stretching

From the very basic raw material 100% virgin PP, we make the PP tape through extruding machine and drawing machine. The know-how of the mixture of raw material and our experienced skill in drawing process, we can manufacture the tread with specified strength. And with the special treatment of the raw material , we can add UV or rediation protection function.

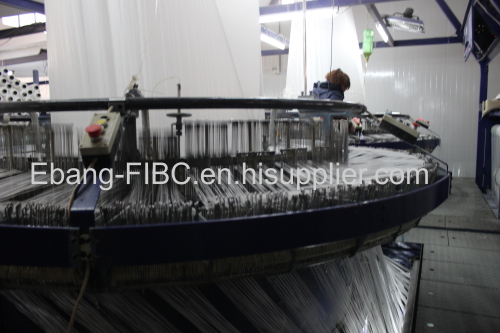

Weaving

And skilled workers weave the tape into plastic coth with Circular looms

Cutting

We are also able to print logos or any draft you provide on the surface of the plastic fabrcs, then cut the plastic cloth into the specified size.

Sewing

The stitchers then sew the fabrics into one bag.

Our Advantage

1.We are the direct factory, best price offer

2. High quality control, Certificate:ISO9001-2008

3. We can provide OEM services for buyers

4. Stable productivity,the shortest delivery time

5. professional technical team

6.Flexible payment terms for old customers.

7.24hours services before and after sales,

make you know clear about the production situation of your order and your container route after shipment.

Packaging & Delivery

Packaging Detail: | 10bag/package or 20bag/package Regular size: 3000px*750px*500px Bearing capacity: 200packages/20'container ,350packages/40'container |

Delivery Detail: | 15days~25days |