Quartz sand storing 4 loop FIBC

| Min. Order: | 2000 Piece/Pieces |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2000T/Year |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | FIBC Big Bag Jumbo Bag, Heavy Duty Woven Polypropylene Fabric Tote, PP Woven Flexible Intermediate Bulk Container, Iron Ore Transport Packaging Container, Custom Made Giant Sack For Australian Buyer |

Product Detail

| Model No.: | U-panel |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Cement |

| Type: | Woven Bag |

| Material: | PP |

| Brand Name: | Ebang |

| Specification: | 91.5x61x61cm |

| Certificate: | ISO9001:2000 |

| Export Area: | USA |

| Lifting Loop: | 4 loops |

| SWL: | 1000kg |

| Color: | White |

| Top: | Open |

| Bottom: | Plain |

| Production Capacity: | 2000T/Year |

| Packing: | Soft Packaging |

| Delivery Date: | 25 Days |

Product Description

Sling Bag is a heavy duty woven polypropylene fabric tote with four 24" polyester lifting loops.

Sling Bag holds fifty-six (56) 60 lb. burlap bags and can be lifted with a single point pick up and lowered into water or onto a land job site.

The Sling Bag is designed to efficiently and safely store, move and place burlap bags in underwater pipe stabilization, protection and separation applications.

The Sling Bag system saves time and is the most economical method of underwater burlap bag placement.

1. Quick Details

--Top Option (Filling): Top Fill Spout

--Loop Option (Lifting): Cross Corner Loop

--Bottom Option (Discharge): Flat Bottom

--Safety Factor: 5:1

--Feature: Breathable

--Loading Weight: 1 ton

--Place of Origin: Anhui, China (Mainland)

--Brand Name: Ebang

--Scientific name: Jumbo Bag

--Material: 100% new pp

--Color: white, yellow, blue

--Weave construction: 13*14

--Usage: Mineral/cement/sand/chemical

--Linner: available

--UV treatment: available

--Printing: available

--Lamination: available

2. Product Specification

Product name | jumbo bag/FIBC/big bag/bulk sack/container bag/Ton bag/super sack |

Material type | 100% pp virgin or lamination fabric |

Construction | 4-panel/U-panel/circular/Tubular/rectangular shape ton FIBC Jumbo Bag |

Fabric weight | 140gsm/160gsm/180gsm/200gsm/240gsm |

Fabic | Laminated/plain/vent |

Loops | 2 or 4 belts, cross corner loop/Double stevedore loop/Side-seam loop |

Ropes | 1 or 2 around the bag body, or customized |

Regular size | 85*85*90cm/90*90*100cm/95*95*110cm or customized |

Top | Top full open/Filling spout/ skirt cover |

Bottom | Flat bottom/discharge spout |

Load capacity | 500 kg-3000kg |

Safe factor | 3:1/5:1/6:1 or customized |

Color | White, yellow or under customers' requirements |

Packing detail | 10pcs/bundle(bale), 20pcs/bundle(bale) or under customers' requirements |

Inside liner | under customers' requirements |

Sewing | Plain/chain/chain lock with optional soft-proof |

Printing | Can be customized ton FIBC Jumbo Bag |

Industrial use | For packing cement, sand, mine, ore, fertilizer, chemical, potato & onion,grain (wheat, maize, rice, peanut, etc.), sugar & salt, agriculture, construction material, powder, and so on. |

Characteristics | Breathable and airy, anti-static, conductive, UV stabilization, reinforcement, dust-proof, moisture-proof |

Document pouch | Yes / No |

Trade Term | CIF, CRF, FOB or other |

Payment Term | T/T (30% of total amount deposit and 70% against B/L copy), L/C at sight |

Delivery time | Within 15-20 days after receipt of your advanced payment |

3. Product Range:

We can customize various kinds of type and size, such as the following:

90 x90x100cm | 90 x90x160cm | 90 x90x140cm | 90 x90x180cm |

90 x90x120cm | 100 x100x100cm | 100 x100x120cm | 100 x100x140cm |

100 x100x160cm | 100 x100x180cm | 95 x95x140cm | 105 x105x210cm |

DIA110x90CM | DIA110X110CM | 105 x105x135cm | 105 x105x240cm |

About us

Anhui YiBang New Material Technology Co., Ltd is proud to call itself one of the most advanced manufacture of FIBCs (bulk bags/big bags/jumbo bags). Our brand Ebang FIBC will meets the specific requirements of your product. In addition, you can use the extensive knowledge of our account managers about the market in which you operate. With our own manufacturing locations in Asia and Africa, we are always able to respond to your individual requirements. Using the sub-menu, you can read more about our long-term partnership. We also look at the manufacturing locations, the advantages of our FIBCs and the fact that we have obtained all of the required certificates. In addition, we would be pleased to provide you with safe handling instructions as well as information about the FIBC configuration and the types of FIBCs.

Please feel free to contact us or complete the answer form. Our expert account managers will be pleased to advise you on the best solution for your product.

Basic Information

1.More than 10 years experience for manufacturing FIBC/ Big Bag

2.Total Number of Employee: 155

3.Number of R & D Staff: 12

4.Factory Area: 10,000 m2

5.Warehouse: 3000m2

6.Whole factory is controlled by ERP-Enterprise Resource Plan

We are provide below ranges of products/service:

1.FIBC/ Big Bag

2.Dry Bulk Liner

3.Flexitank

4.Packaging Optimize Solution

5. Grocery Bag/ Shopping Bag

6.OEM Service

Manufacture Process

Raw material

We use only 100% virgin PP to make sure that our good quality. I can guarantee that you won't find a single grain of second hand PP in our raw material.

Tape Stretching

From the very basic raw material 100% virgin PP, we make the PP tape through extruding machine and drawing machine. The know-how of the mixture of raw material and our experienced skill in drawing process, we can manufacture the tread with specified strength. And with the special treatment of the raw material , we can add UV or rediation protection function.

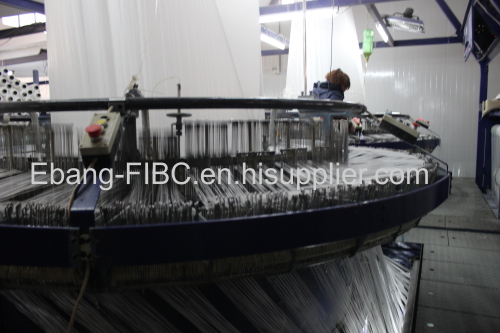

Weaving

And skilled workers weave the tape into plastic coth with Circular looms

Cutting

We are also able to print logos or any draft you provide on the surface of the plastic fabrcs, then cut the plastic cloth into the specified size.

Sewing

The stitchers then sew the fabrics into one bag.

We can customize various kinds of type and size, such as the following:

90 x90x100cm | 90 x90x160cm | 90 x90x140cm | 90 x90x180cm |

90 x90x120cm | 100 x100x100cm | 100 x100x120cm | 100 x100x140cm |

100 x100x160cm | 100 x100x180cm | 95 x95x140cm | 105 x105x210cm |

DIA110x90cm | DIA110X110cm | 105 x105x135cm | 105 x105x240cm |

Our Advantage

1.We are the direct factory, best price offer

2. High quality control, Certificate:ISO9001-2008

3. We can provide OEM services for buyers

4. Stable productivity,the shortest delivery time

5. professional technical team

6.Flexible payment terms for old customers.

7.24hours services before and after sales,

make you know clear about the production situation of your order and your container route after shipment.

Packaging & Delivery

Packaging Detail: | 10bag/package or 20bag/package Regular size: 3000px*750px*500px Bearing capacity: 200packages/20'container ,350packages/40'container |

Delivery Detail: | 15days~25days |

FAQ

Q1: What's your Product Range?

1. Jumbo bag/ ton bag/ big bag/ super sack/ container bag

2. Plastic woven bag, poly-woven bag.

3. Shopping bag.

4. Mesh vegetable fruit bag.

Q2: Are you a manufacture?

Yes, we have been in providing professional solution in plastic woven industry for over 10 years.

Q3: Do you have stock products to sell?

No, we work on OEM orders. That means size material quantity packaging solution, etc will depend on your requests.

Q4: What information should I let you know if I want get a quotation?

-The size of the bag (Length * Width * Height) or (diameter * height)

-The material and surface handing

-The bag's color and the loop's color

-The quantity

-The bag's working condition, service time usage, temperature, the goods save way, light application time.

- If it is possible, please also provide with picture design sketch for checking, sample will be best for clarifying, If not we will recommend relevant products with details for reference.

Q5: How long will the sample be finished? How your factory production scale?

Generally, 1-2 days for sample making.

The lead time of mass production will depend on quantity, quality, and existing orders. Above all can be push as urgent.

Q6: How do you inspect the quality of our order?

We have the perfect methods, equipments, and also expert QC to ensure the quality of products.