Metal wire coil-bound softcover book printing

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 300,000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Hardcover Book, Brochure, Catalog, Softcover Book, Magazine |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Content: | Catalogue |

| Style: | Hardcover |

| Intended Audience: | Adults |

| Brand Name: | Xiandai |

| Size: | 216X279mm |

| Cover material: | Textured paper |

| Inside page material: | Uncoated paper |

| Finishing: | Gold stamping |

| Printing color: | Four color |

| Printing process: | offset printing |

| Spiral coil: | metal |

| Number of inside pages: | no limit |

| Binding: | coil-binding |

| Production Capacity: | 300,000pcs/month |

| Packing: | packed in plastic bag and carton |

| Delivery Date: | 7-10 days after order confirmation |

Product Description

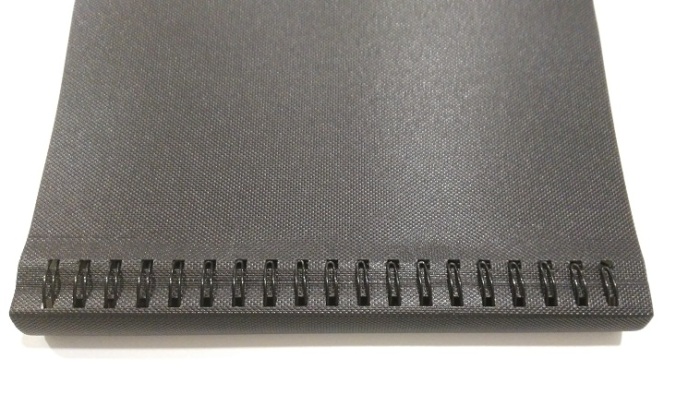

This coil bound book is a softcover book bound by adopting black metal wires or coils, which is round in shape, and most of its coils are hidden by the front cover, and only a small part of coils are exposed through the cuts of its back cover.

Coil binding is called as spiral coil, wire'o coil or spiral binding, etc. Such coil bound book can be opened flat on a desk or table and easy for 360 degree rotation. It is durable, and also available in several colors and sizes.

| Printing | four color offset printing |

| Cover | 250gsm textured paper |

| Finishing | Gloss gold stamping |

| Binding | Spiral coil binding |

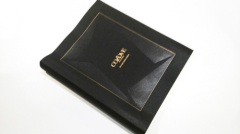

Cover of spiral bound book:

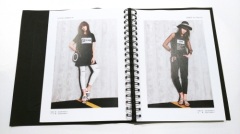

Inside pages of coil bound book:

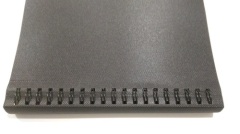

Spine of coil bound book:

Black metal coils of coil bound book:

Gold stamping on coil bound book cover:

FAQ:

1. What are Wire and Spiral binding?

In wire and spiral binding, holes are drilled along one side of the printed pages, and then either a wire comb is clamped down into the holes, or a plastic spiral is threaded through them. Wire and Spiral binding both lay very flat and are often used for cookbooks and manuals.

2. How are such books made?

To create a wire or spiral bound book, parent sheets are first printed, cut and assembled (but not folded, unlike other binding methods). Holes are then drilled into the binding edge of the document. For wire binding, these holes are straight up and down, and for spiral binding they are drilled at a precise angle that depends upon the size and thickness of the book and the plastic spiral used. From there, either wire comb is threaded and clamped down by hand (for wire binding) or spiral is threaded through the holes by hand (spiral binding) to create the final product.

3. What are their design considerations?

The most important thing to remember when designing a wire or spiral bound project is that holes will be drilled 10 millimeters inside the trim line on the bound side of the document. Because of this, we recommend keeping all important content at least 10mm inside of the trim line on the side that will be bound, since any content inside those 10 millimeters may be obscured by the holes drilled or by the binding itself.

Another thing to consider with wire and spiral bound projects is that unlike most other binding methods, your page counts do not have to go in increments of 4. Instead, they can be in increments of 2 (both sides of a sheet of paper), since wire and spiral books do not have to be folded in the binding process.

Finally, wire and spiral pages can have finishes (which are usually reserved for covers) throughout their inside pages. Many manuals designed for outdoor use or cookbooks designed to be spill-resistant will use a lamination on every page.

4. How long does their production time need?

After being sent to press, wire and spiral bound projects take two weeks to manufacture, after which they are shipped out to you via your chosen shipping method. The final delivery time is determined by your proofing and shipping options.